RoboCupMechanical2008

Jump to navigation

Jump to search

This page houses the current RoboCup Mechanical efforts. The 2007 efforts can be found here. All development work will be done in Autodesk Inventor 2008. How to use Inventor and get it can be found on the Inventor How to Guide. Inventor is also available on our CAD Machines in Tin.

Mechanical team meets Tuesday 6-9pm with the general meeting at 7pm and 2-6pm on Sundays. More hours will be announced as deadlines approach.

Contents

Systems

- Drivetrain

- Integration

- Ball Control

- Test Rig

Schedule

- deadline for completion of Everything Box - 11/30/07

- completion of ONE DRIVING, COMPLETE robot - 1/7/08

Specifications

- maximum robot weight - 1.8 kg

- ball speed after being kicked - 10 m/s

- dribbler bar speed - 8000 rpm

- compress time (time for dribbler to absorb ball's energy and compress) - .2 seconds

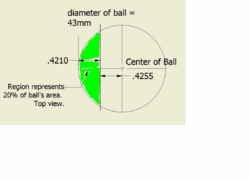

- no more than 20% of the ball's area (seen from top view) may be occupied by the robot - a critical Robocup SSL Rule

Meetings

- 9/6/07 - Update for new members, organized testing plan and ideas

- 9/13/07 - Organized most of the required tests into one device that will be designed starting on monday when we get CAD computer's back in the TIN.

- 9/20/07 - The Test Rig aka "The Everything Box" is being designed and components spec-ed out. The hunt continutes for the dribbler motor.

- 9/24/07 - Everything Box still being designed, would like to start ordering parts on Monday 10/3/07. Idea generation started on the dribbler system such as suspension and damping systems

- 9/27/07 - Test Rig nearing completion. Concepts of ball control system discussed as well as the use of solenoids or some other actuator for the kicker

- 10/1/07 - A cheap treadmill is being looked at for the testing rig. Conceptual planning is being done on the ball control system. Throughout the week, different ideas for the profile of the dribbler will be made on the lathe and then tested.

- the shaft output of the dribbler bar must be 3mm in diameter to fit in the gear of the current dribbler

- 10/4/04 - Dribbler prototypes designed and parts are being ordered to make it. The dribbler motor was chosen and is being ordered as well. Work still continues on the kicker and chipper actuation. Lets work some over fall break! yah...!

- 10/11/07 - Dribbler prototype drawings made. Ball control system still in discussion.

- 10/15/07 - Everything Box design done, parts ordered tomorrow. Drive modules nearing completion.

- 10/18/07 - Everything Box is under construction

- 10/22/07 - Everything Box is under construction, other parts are being designed

- 10/25/07 - Everything Box design complete and parts are being fabricated

- 10/29/07 - Everything Box still being fabricated

- 11/1/07 - No Robocup meeting due to the Virginia Tech football game

- 11/4/07 - No Robocup meeting. Everyone busy.

- 11/7/07 - Mechanical and electrical components for Everything Box being fabricated.

- 11/26/07 - Everything Box is nearly complete, as are the electronics for it. Electronic controls are also nearly done for to control the new drive motors - giving the CS team a platform to use for testing. The machining of a few parts will be outsourced to different suppliers.

- 11/29/07 - Remainder of parts made, as well as some drawings of parts

- 12/2/07 - Everything Box is done, dribbler is nearly finished, drawings still continue to be made to posted for outsourcing

- 12/17/07 - After a break for finals work resumes. Majority of parts ordered for the prototype, design nearly complete - still a bit of tweaking remains. Carbon fiber is being researched for shell.

- 12/18/07 - McMaster order picked up. Kicker solenoid spec-ed out, documentation of design continues.

- 12/19/07 - Spring for the dribbler was designed and selected. position of drive modules will be moved. CAM software tested and g-code created for both drive module plates.

- 12/20/07 - Machining has begun with the drive module inner and outer plates. Roller prototypes for the ominwheels were received and are being evaluated.

- 12/26/07 - Drive module plates completed. Machining begun, slowly, on the omniwheel plates.

- 12/28/07 - Omniwheel plates are complete. The omniwheel bodies arrived and a full omniwheel was assembled - its beautiful. Revisions were made to the rollers based on the wheel and will be sent out. Drive electronics for the Everything Box are being assembled.

- 12/30/07 - The everything box finally has speed control to it. Dribbler parts were machined.

- 1/2/08 - Kicker solenoid was decided upon, preliminary cost analysis performed.

- 1/8/08 - Chipper simulation continues but solution is just about found, machining started on output drive shafts.

- 1/9/08 - Many parts recieved and an output shaft was turned on the lathe. A few other parts have been fabricated.

- 1/15/08 - Drive shafts are done, solenoids have been ordered, alternate supplier was found for drive gears to get them sooner. A game controller was connected to computers to control 2007 robots.

- 1/21/08 - All parts have been lathed. Heat shrink was used for the 2007 dribbler very effectively for qualification

- 1/22/08 - Bottom plate was machined, the kicking testing equipment has been started as well as the dribbler-incline test was nearly completed

- 1/27/08 - G-code written for chipper parts. Dribbler gears were re-spec-ed out, discussion of TDP has begun, layout of the electrical board was decided to accomodate for the mechanical design

Documentation

Testing

Quick Notes

- field area 5 meters x 3.5 meters

- max ball speed - 10 m/s

- ball diameter - 43 mm

- ball mass - 46 grams

- 1 rpm = .105 rad/s

- ball material - DuPont Surlyn Ionomer Dupont's Surlyn Page

- coefficient of static friction of golf ball on felt carpet - .66

- last two points from Cornell 2003 Mechanical Documentation

Parts

Prototype Notes

- make drive module shaft out of stronger material to prevent bending

Useful Links

- Cornell Documents (Look at 2003)

- MIT Design Handbook Index (VERY GOOD)