Difference between revisions of "Bucki"

(→Bucki V1.0) |

m (Naming convention) |

||

| (16 intermediate revisions by 3 users not shown) | |||

| Line 60: | Line 60: | ||

|- | |- | ||

| Drive Motor Controllers | | Drive Motor Controllers | ||

| − | | HobbyKing Brushless Car ESC 2S-4S | + | | HobbyKing Brushless Car ESC 2S-4S (This was based on lessons learned at Motorama. Original ESCs were not Car ESC) |

|- | |- | ||

| Weapon Motor | | Weapon Motor | ||

| Line 85: | Line 85: | ||

====Design Overview==== | ====Design Overview==== | ||

| − | + | BLANK | |

====Design Decisions==== | ====Design Decisions==== | ||

| − | + | BLANK | |

| − | |||

| − | |||

| − | |||

| − | |||

====Evaluation==== | ====Evaluation==== | ||

| − | + | BLANK | |

| − | |||

| − | |||

| − | |||

| − | |||

=== Drive Assembly === | === Drive Assembly === | ||

| Line 106: | Line 98: | ||

====Design Decisions==== | ====Design Decisions==== | ||

| − | + | We made the incorrect assumption that our drive ESCs were reversible. That was not true, and even further we did not learn this until <i>AT</i> Motorama. | |

====Calculations==== | ====Calculations==== | ||

| − | + | We only matched the supported output ampage to the max current draw of our drive motors. Physical dimensions were the most relevent to our calculations. | |

| − | |||

====Evaluation==== | ====Evaluation==== | ||

| − | + | BLANK | |

| + | |||

| + | ===Weapon Assembly=== | ||

| + | ====Overview==== | ||

| + | BLANK | ||

| − | + | ====Design Decisions==== | |

| + | BLANK | ||

| − | + | ====Calculations==== | |

| + | BLANK | ||

| + | ====Evaluation==== | ||

| + | BLANK | ||

| − | === | + | ===Electronics=== |

====Overview==== | ====Overview==== | ||

| − | + | BLANK | |

====Design Decisions==== | ====Design Decisions==== | ||

| − | + | BLANK | |

====Calculations==== | ====Calculations==== | ||

| − | + | BLANK | |

| + | |||

====Evaluation==== | ====Evaluation==== | ||

| − | + | BLANK | |

| − | + | === Pneumatics === | |

| − | + | ====Design Overview==== | |

| − | ====Overview==== | + | As a flipper, Bucki launches its opponents into the air using rapid, impulsive force. To this end, it utilizes a liquid CO2 system to power an air cylinder and actuate its flipping motion. The liquid CO2 is stored in pre-filled 20 gram cartridges, which are inserted into a specialty regulator to reduce the operating pressure to an amount manageable by the most fragile elements of the design. |

| − | + | ||

| + | Upon exiting the regulator, the decompressed CO2 is held upstream of a 3 port/2 state solenoid valve, which allows for intake of air into the piston and exhaust following the end of its stroke. This solenoid is controlled using signals from a standard RC controller interpreted by a microcontroller. | ||

| + | |||

| + | Also upstream of the solenoid valve, the system features a bleed valve to empty the system following operation and a pressure gauge to monitor the regulator’s output. These components are connected with a variety of connectors and lengths of tubing. | ||

| + | |||

| + | A full component list can be found in the safety documentation below. | ||

| + | |||

| + | [[File:BuckiPneumaticSystem.png|thumb|center|400px|Bucki Pneumatics Diagram]] | ||

====Design Decisions==== | ====Design Decisions==== | ||

| − | + | *A liquid CO2 system was chosen for its small form factor and reduced weight relative to the standard HPA design. | |

| + | **HPA necessitates a larger tank that needs to be recharged, while CO2 cartridges can be switched out rapidly. | ||

| + | **Recharging a HPA tank would require a more powerful air compressor (such as a SCUBA or paintball one) than the ones that are easily available on campus. | ||

| + | **HPA operates at pressures and capacities that are excessive for the other limits imposed on the system. | ||

| + | *The specialty regulator was chosen for its ability to pierce CO2 cartridges and convert their input to a standard NPT size. | ||

| + | *The solenoid valve chosen was decided based on its low weight and size, but other options (such as some valves from Parker) would have been superior in terms of pressure and power. | ||

| + | *Tube adapters were used on components expected to be moved by operators or during weapon actuation (piston, gauge and regulator). | ||

| + | *The system was primarily constrained by weight and size and would've been better served with a larger piston and greater pressure. | ||

| + | *NERC rules were relatively loose, but they required the use of a gauge and a method to bleed the system. | ||

| + | *Liquid CO2 when decompressing to a gaseous state undergoes an endothermic reaction that rapidly cools the components and reduces the tank pressure. | ||

====Calculations==== | ====Calculations==== | ||

| − | + | I need to go hunt these down lmao | |

====Evaluation==== | ====Evaluation==== | ||

| − | + | *Pneumatics are incredibly difficult at a 12lb weight class according to officials at Motorama, so it existing is kind of impressive. | |

| + | *The system was able to actuate more than 15 times rapidly without issue. | ||

| + | *It was never used to flip anything and it is still unknown whether it matched the calculation or was sufficiently powerful. | ||

| + | *It had various issues that made assembly difficult: | ||

| + | **Some components did not match spec sheets and required the system to be modified. | ||

| + | **Modifications required deviation from initial placement plan which made fitting system in chassis difficult. | ||

| + | **Chassis had no systems to aid in assembly or constrain parts. | ||

| + | *Future robots using pneumatics should use HPA at a higher weight class. | ||

| + | |||

| + | ====Links==== | ||

| + | [https://docs.google.com/document/d/1vJr__bwY3fGl827ZOihG8hrwaWbd_oc0wv8mEKBof2Q/edit?usp=sharing Safety Documentation] | ||

= See also = | = See also = | ||

| Line 155: | Line 181: | ||

| − | <span style="line-height: 20.7999992370605px">Naming Inspiration: | + | <span style="line-height: 20.7999992370605px">Naming Inspiration: Metal arm similar to the Marvel character Bucki, also bucks other bots like a rodeo bull; should've been Topsi Turvi</span> |

<span style="line-height: 20.7999992370605px">Took least amount of damage of any bot in Motorama history</span> | <span style="line-height: 20.7999992370605px">Took least amount of damage of any bot in Motorama history</span> | ||

| + | [[Category:BattleBots]] | ||

[[Category:HobbyWeights]] | [[Category:HobbyWeights]] | ||

| + | [[Category:BigBots]] | ||

Latest revision as of 20:27, 28 May 2022

| Bucki | |

|---|---|

| Year Of Creation | 2021-2022 |

| Versions | |

| Current Version | V 1.0 |

| Update Year | 2021-2022 |

| Wins/Losses | 0/2 |

| Information and Statistics | |

| Weight Class | Hobbyweight |

| Weapon Class | Pneumatic Flipper |

| Combined Wins/Losses | 0/2 |

| Weapon Speed | Around 80000? |

| Other | Never moved lol |

Bucki is not the first iteration of a 18 lb Bent Bar Shuffler. Bucki is unfortunately the first iteration of the 12 lb pneumatic flipper. The purpose of this guide is to explain all of the reasoning behind the design decisions during the creation of Bucki. This guide will go in depth on why certain designs were chosen as well as explaining some of the calculations used to support those decisions.

Contents

Competitions

Motorama 2022

- Results:

- Bracket Style: Double Elimination

- Loss vs Hocki lmao

- Bot did not move and we immediately gave up

- "Victory by intimidation"

- Loss vs Who Knows?

- Bot did not fire and we immediately gave up

- Loss vs Hocki lmao

- Bracket Style: Double Elimination

Bucki V1.0

Created by: Daniel Johnson, Martha Leach, Mesum Zaidi, Natalie Van Slyke, Scott Janssen, Keaton Sadoski, Samuel Alzate, Anthony DeCesaris, Paul Barsa

| Drive Motors | Turnigy 540L V-Spec Inrunner 810kv |

| Drive Motor Controllers | HobbyKing Brushless Car ESC 2S-4S (This was based on lessons learned at Motorama. Original ESCs were not Car ESC) |

| Weapon Motor | wind |

| Weapon Motor Controllers | YEP 100A (2~6S) SBEC Brushless Speed Controller |

| Receiver | Hobby King 2.4Ghz Receiver 6Ch V2 |

| Remote Control | Hobby King 2.4Ghz 6Ch Tx and Rx V2 |

| Battery | 2x Turnigy 2200mAh 4S 30C Lipo Pack |

| (OTHER:) | MS-05 Switch |

Chassis

Design Overview

BLANK

Design Decisions

BLANK

Evaluation

BLANK

Drive Assembly

Overview

Bucki’s Drive system was not.

Design Decisions

We made the incorrect assumption that our drive ESCs were reversible. That was not true, and even further we did not learn this until AT Motorama.

Calculations

We only matched the supported output ampage to the max current draw of our drive motors. Physical dimensions were the most relevent to our calculations.

Evaluation

BLANK

Weapon Assembly

Overview

BLANK

Design Decisions

BLANK

Calculations

BLANK

Evaluation

BLANK

Electronics

Overview

BLANK

Design Decisions

BLANK

Calculations

BLANK

Evaluation

BLANK

Pneumatics

Design Overview

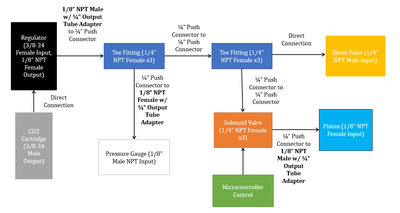

As a flipper, Bucki launches its opponents into the air using rapid, impulsive force. To this end, it utilizes a liquid CO2 system to power an air cylinder and actuate its flipping motion. The liquid CO2 is stored in pre-filled 20 gram cartridges, which are inserted into a specialty regulator to reduce the operating pressure to an amount manageable by the most fragile elements of the design.

Upon exiting the regulator, the decompressed CO2 is held upstream of a 3 port/2 state solenoid valve, which allows for intake of air into the piston and exhaust following the end of its stroke. This solenoid is controlled using signals from a standard RC controller interpreted by a microcontroller.

Also upstream of the solenoid valve, the system features a bleed valve to empty the system following operation and a pressure gauge to monitor the regulator’s output. These components are connected with a variety of connectors and lengths of tubing.

A full component list can be found in the safety documentation below.

Design Decisions

- A liquid CO2 system was chosen for its small form factor and reduced weight relative to the standard HPA design.

- HPA necessitates a larger tank that needs to be recharged, while CO2 cartridges can be switched out rapidly.

- Recharging a HPA tank would require a more powerful air compressor (such as a SCUBA or paintball one) than the ones that are easily available on campus.

- HPA operates at pressures and capacities that are excessive for the other limits imposed on the system.

- The specialty regulator was chosen for its ability to pierce CO2 cartridges and convert their input to a standard NPT size.

- The solenoid valve chosen was decided based on its low weight and size, but other options (such as some valves from Parker) would have been superior in terms of pressure and power.

- Tube adapters were used on components expected to be moved by operators or during weapon actuation (piston, gauge and regulator).

- The system was primarily constrained by weight and size and would've been better served with a larger piston and greater pressure.

- NERC rules were relatively loose, but they required the use of a gauge and a method to bleed the system.

- Liquid CO2 when decompressing to a gaseous state undergoes an endothermic reaction that rapidly cools the components and reduces the tank pressure.

Calculations

I need to go hunt these down lmao

Evaluation

- Pneumatics are incredibly difficult at a 12lb weight class according to officials at Motorama, so it existing is kind of impressive.

- The system was able to actuate more than 15 times rapidly without issue.

- It was never used to flip anything and it is still unknown whether it matched the calculation or was sufficiently powerful.

- It had various issues that made assembly difficult:

- Some components did not match spec sheets and required the system to be modified.

- Modifications required deviation from initial placement plan which made fitting system in chassis difficult.

- Chassis had no systems to aid in assembly or constrain parts.

- Future robots using pneumatics should use HPA at a higher weight class.

Links

See also

- [(link to other bot made this year) (Name of other bot made this year)]

Notes:

Naming Inspiration: Metal arm similar to the Marvel character Bucki, also bucks other bots like a rodeo bull; should've been Topsi Turvi

Took least amount of damage of any bot in Motorama history