Difference between revisions of "Hocki"

(→Controls and Data Logging) |

(→Mounting) |

||

| Line 92: | Line 92: | ||

Thermal pads used to adhere ESCs to bottom plate. Thin metal bar screwed to bottom plate above ESCs to improve stability and limit movement. | Thermal pads used to adhere ESCs to bottom plate. Thin metal bar screwed to bottom plate above ESCs to improve stability and limit movement. | ||

PCB holder screwed into bottom and top plates. PCB is mounted onto 3D-printed PCB holder using 4 screws and rubber spacers. | PCB holder screwed into bottom and top plates. PCB is mounted onto 3D-printed PCB holder using 4 screws and rubber spacers. | ||

| + | |||

| + | [[File:IMG_1145.jpg|200px|Drive Train Mount]] | ||

=== Electronics === | === Electronics === | ||

Revision as of 18:56, 25 February 2022

| Hocki | |

|---|---|

| Year Of Creation | 2020-2021 |

| Versions | |

| Current Version | 1.0 |

| Update Year | 2020-2022 |

| Wins/Losses | 1/2 |

| Information and Statistics | |

| Weight Class | Hobby Weight |

| Weapon Class | (Translational Drift Spinner/Meltybrain) |

| Combined Wins/Losses | 1/2 |

| Weapon Speed | 3600 RPM |

Hocki is a Meltybrain, a combat robot that spins itself to attack. Unlike other robots, which have a stationary frame and spinning weapon, in this robot the entire frame is the weapon, and the robot spins itself to attack. This allows the robot to store more energy while spinning slower, which allows for hits to connect better. Such a design requires a control system which uses sensors to estimate the position of the robot. This robot utilizes custom circuitry and software to allow the frame to move, spin, and attack.

Contents

Competitions

Due to COVID-19 this robot did not go to competitions.

Design

(Hocki) V1.0

Team Lead: Valentin Richter

Team Mentor: Varun Madabushi

Members: John Bowzard, Kevin Xiao, Madeline Belew, Steven Zhao

| Drive Motors | Scorpion HKIV-4020-860KV |

| Drive Motor Controllers | iFlight SucceX X80A |

| Receiver | FS-A8S |

| Remote Control | FS-i6X |

| Battery | 2x Turnigy Graphene Panther 1200mAh 6S 75C Battery Pack w/XT60 |

| (OTHER:) |

Mechanical

Overall Design and Construction

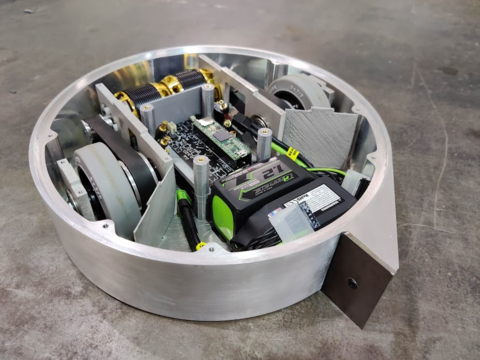

The robot is comprised of an aluminum ring with aluminum top and bottom plates bolted on. All interior components (electronics, drive assembly) are sandwiched between the two rings.

One priority in the design is increasing the moment of inertia as much as possible by moving heavier components outwards. The main structure of the robot is the aluminum ring, which is CNC machined out of a single piece. This CNC machined part was ordered from Xometry due to obstacles in HAAS training and shop access due to the COVID-19 pandemic. After receiving the ring, it was tapped to accept screws which hold the top and bottom plates as well as the impactor tooth. The top and bottom plates were machined on the waterjet cutter and sanded to fit the grooves in the ring, as well as the motor and wheel mounts.

Another priority is keeping the center of mass centered at the midpoint of the wheels. If it were not, the kinematic center of rotation would be far from the dynamic center of rotation, resulting in drift and preventing the accelerometers from accurately measuring the centripetal acceleration. Thus care is taken in the placement of interior and exterior components to balance the robot.

We selected a 1-tooth design as the 1 tooth can cancel the weight of the motors in the back.

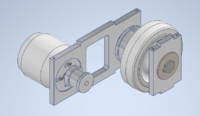

Drive

Describe structures/mechanisms here such as Drive, Ring, yada yada

Mounting

Drive train mounts screwed into both top and bottom plates and allow for assembly of wheel, motor, and pulley system.

Thermal pads used to adhere ESCs to bottom plate. Thin metal bar screwed to bottom plate above ESCs to improve stability and limit movement. PCB holder screwed into bottom and top plates. PCB is mounted onto 3D-printed PCB holder using 4 screws and rubber spacers.

Electronics

Overall Design

Control Board

IR Transmitter/Detector

LED Board

Software

Overall Design

Low-Level Systems

Controls and Data Logging

We derived equations to calculate rotational velocity from measured centripetal acceleration without needing to know the exact center of mass by using data from a pair x or y measurements from the accelerometers. With this method, we calculated four rotational velocities and averaged them to find the rotational velocity of the robot with minimized noise. We then integrated this velocity to get the angle the robot was oriented, setting zero to be the initial direction the robot was facing. However, even with this method we found that the position of the robot would drift at rest but was relatively accurate at higher rotational speeds.

To translate while spinning, we alternated pulsing the left and right motor speeds, each for half of a rotation, which is illustrated in the below image. However, during competition we were not able to translate in a controlled direction, rather translating in one random direction regardless of controller input.

We logged each axis of every accelerometer, as well as the average rotational velocity and the position of the robot at a frequency of 20 Hz. We stored this data in a .txt file on an SD card inserted onto the Teensy board. For the logging, we added 16 lines of data to a buffer before flushing the lines to the file.

See also

Notes:

Named after its resemblance to a hockey puck

Original Builders: Afshan Chandani, Varun Madabushi, Juan Elizondo, Hank Hellstrom, Darren Kosen, Nelson Jiang, Valentin Richter, Kevin Xiao, Sarkis Ter Maritorsyan, Keaton Sadoski, Alex Yu