Difference between revisions of "RC08-Kicker"

Jump to navigation

Jump to search

| Line 3: | Line 3: | ||

[[RobocupMechanical|Robocup 2008 Mechanical]] | [[RobocupMechanical|Robocup 2008 Mechanical]] | ||

| − | |||

| − | |||

| − | |||

| − | [http://www.solenoidcity.com/solenoid/tubular/s-20-125hp1.htm | + | ==Assembly Structure== |

| + | {| border="1" cellpadding="2" | ||

| + | !width="225"|PART NAME | ||

| + | !width="100"|PART NUMBER | ||

| + | !width="50"|QUANTITY | ||

| + | |- | ||

| + | |Solenoid Mount || RC-2008-05-01 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Kicker Solenoid Tube|| RC-2008-05-02 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Kicker Solenoid Plunger || RC-2008-05-03 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |3/4 Hex Nut|| RC-2008-05-04 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Boot || RC-2008-05-05 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |6-32 x 1/4" Screw || RC-2008-05-06 || 2 | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | ==Parts & Components== | ||

| + | ===Solenoid=== | ||

| + | :Vendor: Solenoid City | ||

| + | :Part No.: SOTUH032051 | ||

| + | :Description: S-20-125-H push solenoid, 1.25" in diameter, 2" long, 120V at 10% duty cycle | ||

| + | :Cost: $48.88 each | ||

| + | |||

| + | * [http://www.solenoidcity.com/ MicroMo] | ||

| + | * [http://www.solenoidcity.com/solenoid/tubular/s-20-125hp1.htm Solenoid Data Sheet] | ||

| + | |||

| + | |||

| + | * Electrical specification | ||

| + | ** capable of 300V pulse | ||

| + | |||

| + | ===Return Springs=== | ||

| + | * 4 different return springs for this solenoid, all 4 were purchased and one will be evaluated. | ||

| + | |||

| + | ===Hex Nut=== | ||

| + | *5/32" thick, 7/8" between flats hexagonal nut with threads: 3/4-18 - UNF-2A | ||

| + | |||

| + | ===Plates=== | ||

| + | =====Solenoid Mount===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 3511T11 | ||

| + | :Description: Alloy 6061 Aluminum Ground Flat Stock .250" Thick, 6" X 6" Size | ||

| + | :Cost: $45.44 each - STOCK | ||

| + | *Holds solenoid and mounts it to the drive plate | ||

| + | *Screws on the side constrain range of chipper | ||

| + | |||

| + | =====Boot===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 8885K13 | ||

| + | :Description: Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12" | ||

| + | :Cost: $21.73 | ||

| + | *Supports motor and connects to the 2 spacers in assembly | ||

| + | *Material is same and shared with Omniwheel plates | ||

| + | |||

| + | |||

| + | ===Fasteners=== | ||

| + | =====6-32 x 1/4" socket cap screw===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 92220A141 | ||

| + | :Description: 6-32 x 1/4" steel, low profile, socket cap screw | ||

| + | :Cost: $7.22 for 25 | ||

| + | *Provides limitation to chipper angle | ||

==Calculations== | ==Calculations== | ||

| − | + | =====Torsion Spring===== | |

| − | * | + | * Analysis was done using the Work-Energy Principle with the assumption that the only work done is from the torsion spring and gravity. Because the dribbler assembly swings and has zero velocity at both positions, only the kinetic energy of the ball was used, at its maximum value of 10 m/s |

| − | * | + | |

| + | =====Roller Speed===== | ||

| + | * Gears were selected for a gear ratio lower than 2007. The 2008 ratio is 1.5. This was with the hope of having more torque available for the roller to grip the ball. | ||

| + | |||

| + | ==Notes== | ||

| + | * 4mm steel shaft chosen to increase strength to prevent bending of dribbler shaft when hit with a ball | ||

| + | *roller diameter - .5" | ||

| + | *dribbler shaft still slides free in between two snap-in thrust bearings and can be removed to allow the roller to be changed out | ||

| − | == | + | ==Dribbler bar prototypes== |

| − | * | + | *shaft diameter on ends of bar - 3mm |

| − | * | + | *maximum diameter of dribbler - .75" |

| − | * | + | *the dribbler bar prototypes will be lathed and done coated with neoprene heat shrink |

| − | + | [[image:dribblerprototype.png|500 px|Dribbler bar prototype drawing]] | |

| − | * | + | ===dribbler bar prototypes=== |

| − | * | + | *3/4" diameter aluminum bar stock |

| + | **$8.34 | ||

| + | **McMaster part number 6750K181 | ||

| + | *3mm diameter aluminum bar stock | ||

| + | **$6.94 | ||

| + | **McMaster part number 1681T21 | ||

| + | *3/4" neoprene heat shrink | ||

| + | **pack of 5 for $8.97 | ||

| + | **McMaster part number 7505K86 | ||

| + | *3mm e-clips | ||

| + | **pack of 100 for $3.03 | ||

| + | **McMaster part number 98543A101 | ||

| − | === | + | ==2007 Dribbler== |

| − | * | + | ===Drive gear=== |

| − | * | + | *attached to the motor |

| + | *SDP/SI A-1B-2MYK05045 [https://sdp-si.com/eStore/..%5Css%5CPDF%5CSSUM7025.PDF Data sheet] | ||

| + | *45 teeth, 3mm bore, 22.5mm pitch diameter | ||

| + | ===Dribbler gear=== | ||

| + | *attached to the roller. This is done by pressing having a set screw in the gear interfere with the roller. Both the gear and roller are free to spin on the shaft, which permitting easy change. | ||

| + | *SDP/SI A-1B-2MYKO5020H [https://sdp-si.com/eStore/..%5Css%5CPDF%5CSSUM7025.PDF Data sheet] | ||

| + | *20 teeth, 3mm bore, 10mm pitch diameter | ||

| − | * | + | *gear ratio from motor to drilbber = 2.25 |

| − | + | ===Motor=== | |

| − | + | *15.9mm diameter, 3mm output shaft | |

| − | * | + | ==Specs from CMU== |

| + | *Dribbler motor gear from SDP-SI: S10T05M042A0303 Module 0.5, 42 Teeth, 20° Pressure Angle , 2024 Aluminum alloy Gear | ||

| + | *Dribbler bar gear from SDP-SI: S10T05M028A0305 Module 0.5, 28 Teeth, 20° Pressure Angle , 2024 Aluminum alloy Gear | ||

| + | *spur gear reduction 1:1.5 | ||

| + | *Dribbler Motor - Maxon | ||

| + | **266521 | ||

| + | **http://test.maxonmotor.com/docsx/Download/catalog_2007/Pdf/07_154_e.pdf | ||

| + | **nominal speed 28200 rpm | ||

| + | *Gearhead | ||

| + | **118184 - Maxon | ||

| + | **http://test.maxonmotor.com/docsx/Download/catalog_2007/Pdf/07_215_e.pdf | ||

| + | **reduction 5.4:1 | ||

| + | *nominal dribbler bar speed = 28200/5.4*1.5 = 7833 RPM. It is, of course, adjustable by software. | ||

Revision as of 15:11, 13 January 2008

This page contains the information and documentation of the 2008 kicker system

Contents

Assembly Structure

| PART NAME | PART NUMBER | QUANTITY |

|---|---|---|

| Solenoid Mount | RC-2008-05-01 | 1 |

| Kicker Solenoid Tube | RC-2008-05-02 | 1 |

| Kicker Solenoid Plunger | RC-2008-05-03 | 1 |

| 3/4 Hex Nut | RC-2008-05-04 | 1 |

| Boot | RC-2008-05-05 | 1 |

| 6-32 x 1/4" Screw | RC-2008-05-06 | 2 |

Parts & Components

Solenoid

- Vendor: Solenoid City

- Part No.: SOTUH032051

- Description: S-20-125-H push solenoid, 1.25" in diameter, 2" long, 120V at 10% duty cycle

- Cost: $48.88 each

- Electrical specification

- capable of 300V pulse

Return Springs

- 4 different return springs for this solenoid, all 4 were purchased and one will be evaluated.

Hex Nut

- 5/32" thick, 7/8" between flats hexagonal nut with threads: 3/4-18 - UNF-2A

Plates

Solenoid Mount

- Vendor: McMaster-Carr

- Part No.: 3511T11

- Description: Alloy 6061 Aluminum Ground Flat Stock .250" Thick, 6" X 6" Size

- Cost: $45.44 each - STOCK

- Holds solenoid and mounts it to the drive plate

- Screws on the side constrain range of chipper

Boot

- Vendor: McMaster-Carr

- Part No.: 8885K13

- Description: Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12"

- Cost: $21.73

- Supports motor and connects to the 2 spacers in assembly

- Material is same and shared with Omniwheel plates

Fasteners

6-32 x 1/4" socket cap screw

- Vendor: McMaster-Carr

- Part No.: 92220A141

- Description: 6-32 x 1/4" steel, low profile, socket cap screw

- Cost: $7.22 for 25

- Provides limitation to chipper angle

Calculations

Torsion Spring

- Analysis was done using the Work-Energy Principle with the assumption that the only work done is from the torsion spring and gravity. Because the dribbler assembly swings and has zero velocity at both positions, only the kinetic energy of the ball was used, at its maximum value of 10 m/s

Roller Speed

- Gears were selected for a gear ratio lower than 2007. The 2008 ratio is 1.5. This was with the hope of having more torque available for the roller to grip the ball.

Notes

- 4mm steel shaft chosen to increase strength to prevent bending of dribbler shaft when hit with a ball

- roller diameter - .5"

- dribbler shaft still slides free in between two snap-in thrust bearings and can be removed to allow the roller to be changed out

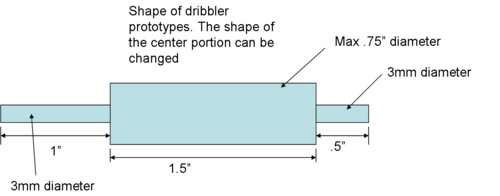

Dribbler bar prototypes

- shaft diameter on ends of bar - 3mm

- maximum diameter of dribbler - .75"

- the dribbler bar prototypes will be lathed and done coated with neoprene heat shrink

dribbler bar prototypes

- 3/4" diameter aluminum bar stock

- $8.34

- McMaster part number 6750K181

- 3mm diameter aluminum bar stock

- $6.94

- McMaster part number 1681T21

- 3/4" neoprene heat shrink

- pack of 5 for $8.97

- McMaster part number 7505K86

- 3mm e-clips

- pack of 100 for $3.03

- McMaster part number 98543A101

2007 Dribbler

Drive gear

- attached to the motor

- SDP/SI A-1B-2MYK05045 Data sheet

- 45 teeth, 3mm bore, 22.5mm pitch diameter

Dribbler gear

- attached to the roller. This is done by pressing having a set screw in the gear interfere with the roller. Both the gear and roller are free to spin on the shaft, which permitting easy change.

- SDP/SI A-1B-2MYKO5020H Data sheet

- 20 teeth, 3mm bore, 10mm pitch diameter

- gear ratio from motor to drilbber = 2.25

Motor

- 15.9mm diameter, 3mm output shaft

Specs from CMU

- Dribbler motor gear from SDP-SI: S10T05M042A0303 Module 0.5, 42 Teeth, 20° Pressure Angle , 2024 Aluminum alloy Gear

- Dribbler bar gear from SDP-SI: S10T05M028A0305 Module 0.5, 28 Teeth, 20° Pressure Angle , 2024 Aluminum alloy Gear

- spur gear reduction 1:1.5

- Dribbler Motor - Maxon

- 266521

- http://test.maxonmotor.com/docsx/Download/catalog_2007/Pdf/07_154_e.pdf

- nominal speed 28200 rpm

- Gearhead

- 118184 - Maxon

- http://test.maxonmotor.com/docsx/Download/catalog_2007/Pdf/07_215_e.pdf

- reduction 5.4:1

- nominal dribbler bar speed = 28200/5.4*1.5 = 7833 RPM. It is, of course, adjustable by software.

2007 Solenoid

- Solenoid from '07 season. S-20-100-H from Solenoid City, ~ $39

- S-20-100-H

Kicker plate

- must be aluminum - doesn't deform as much as plastic, and ligther than steel

Ball Speed

- goal: 10m/s