Difference between revisions of "How to be BattleBots Project Manager"

Ndaugherty6 (talk | contribs) |

Athrasher7 (talk | contribs) m |

||

| Line 1: | Line 1: | ||

| − | [[Category:How to Guides]] | + | [[Category:How to Guides: Administrative]] |

[[Category:BattleBots]] | [[Category:BattleBots]] | ||

Welcome to BattleBots Project Management. The purpose of this document is to guide future project managers as they take on the role and to serve as a reference for future BattleBot’s members. | Welcome to BattleBots Project Management. The purpose of this document is to guide future project managers as they take on the role and to serve as a reference for future BattleBot’s members. | ||

Latest revision as of 21:53, 5 February 2020

Welcome to BattleBots Project Management. The purpose of this document is to guide future project managers as they take on the role and to serve as a reference for future BattleBot’s members.

Contents

What is your job?

While answers may vary, I see the role of Battlebots Project Manager as the driving force behind the robots, without actually building the robots. Looking at the team as a “robot building machine,” the team members are the various components which actually build the robots. While people will not be as reliable as mechanical parts, the role of the project manager is still to facilitate their work. It is not the PMs job to machine parts, be the best machinist, or have the most knowledge about robotics. The Project Manager is responsible for making sure the “robot building machine” functions as efficiently as possible.

The specific duties of the PM are as follows:

- Appoint robot leads

- Set the schedule for each bot’s progress

- Schedule design reviews

- Monitor the progress of the robots

- Take action if a robot falls behind

- Register for competitions

- Work with the robot leads to create a budget

- Make sure spending does not exceed budget

- Make sure the shop is clean after meetings

- Make sure new members are sticking around and taking on leadership positions

- Ensure these active members receive the leadership advice and training they need(in this case, “training” is practice doing something ex. leading)

- Ensure active members get a chance to practice leadership even if they don’t want or receive a position. RJ needs people who lead, even if they do not have a title

- In order to be an effective leader, you need to be able to rely on your team being productive without you present

- Ensure new members take advantage of opportunities to learn from the work of more senior members, both CAD, machining, and other technical skills

- Ensure older members are teaching new members these skills

Communication:

You need to make sure you are communicating with your team effectively. Make sure every member is kept updated on the current progress of the robots and make sure you are aware of the current progress of each robot. An important part of staying on schedule is identifying roadblocks before/when they occur. You can’t solve a problem until you fully understand the cause. You are also not responsible for solving the problem yourself, only seeing that the problem is solved.

You need to set a timeline for each robot from the beginning of the year to the competition. This timeline should have specific checks for progress, and the robot leads should agree that the timeline is reasonable. If they miss a progress check, you need to work with them to get back on schedule ASAP. You should also make sure the rest of the team is updated on the progress of every robot.

Regularly ask robot leads:

- What they have accomplished

- What they are doing next

- What they need to continue work

- This may include outside expertise, knowledge, or human resources; it is not limited to materials/time

Make sure every member working on the robot is up to date on the progress and knowledgeable of the robot.

Take notes. If something is said that you want an action to come from, write it down. Memory is often bad, and you’ll forget more than you expect. Often, a conversation about long term goals or about a list of things to do will happen spontaneously. You need to make sure all of this actually happens or is taken into account for future decision making.

Lastly, make sure everyone gets along. If you or a team member is having a personal issue with another team member, you need to sit down, and talk it out. Make sure there is mutual respect. Without this respect, your team members will not communicate effectively with you or each other.

Below is a spread sheet previously used to track the progress of the robots. It's advantage is allowing you to see whether the robot is accomplishing previously set goals, and to easily examine the progress made over time. The expectations must be set ahead of time and revisited throughout the semester. The accomplished is what was actually completed at the time of the check, and it is filled via report from the robot lead. If the expectation was not met, plans to meet the expectation should be added.

| Check Dates | Robot 1 Expectation | Robot 1 Accomplished | Robot 2 Expected | Robot 2 Accomplished | And so on for N robots |

|---|---|---|---|---|---|

| mm/dd/yyy | Have Design Reviewed | Robot was successfully design reviewed | Have Chassis Finished | One plate left to machine (will be done tomorrow) | |

| mm/dd/yyy | Design changes made and

next design review planned |

Changes made, but next review has not

been planned |

Have robot driving | Robot will be driving tonight | |

| mm/dd/yyy | Design review complete | weapon assembly done |

The Robot Build Process:

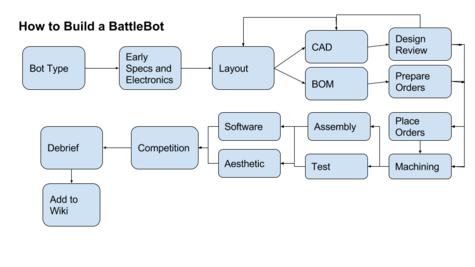

To the right is the high level process for building a robot. You should expect your robot leads to accomplish all of these steps in some form or another.

You must also make sure that the robot leads are progressing through these steps. If they have been working on “CAD” for an entire semester, they are likely behind schedule. Monitoring a robot’s timeline is crucial for making sure the robot is complete. Members will work on the robot, but you must make sure enough work is being done.

Registering for Competition:

Registering for competition should be completed as soon as possible. Googling your desired competition and clicking “register” should give you a starting point. You should know the dates, rules, and location of the competition months in advance. In the past, registrations have filled over night, and so you need to make sure you are proactive when registering for competition.

The process for registration is as follows:

- Decide you are going to set competition

- Check rules, requirements for entry, registration dates, etc.

- Decide which robots will be going

- Decide which people are going (~1month before registration opens)

- Collect necessary information about those team members/enter them into whatever database the competition uses

- Register for the competition (~1-3 days within registration opening)

- Contact Faculty sponsor for permission to go to competition and for excused absence forms.

- Pay for competition (Some competitions have a delay in when payment is due and when you can register). Do this as soon as possible, some registrations are expensive or require physical check. This can take additional time.

- Book lodging and travel as necessary (hotel 1-2 months in advance, travel 2-4 months in advance)

- Decide how much each going member will pay and collect the amount before traveling

- Wait for the competition to contact you with info about what to do when you arrive

- Make sure you receive passes if they are being shipped to you

Registering for Motorama:

Website: https://www.motoramaevents.com/

Motorama has been our new member’s intro competition. Given it is the “freshman competition,” the main focus should be taking as many new members as possible. You only need enough senior members to drive the cars and maybe one or two more to help corral new members. We have historically taken about 21 members. Senior members may bring a 30 lb robot as well.

- Motorama - Builder’s database - Use this to manage our team and robots. This site can also be used for other competitions

- Contact an old PM for the login info

- New team members can be added via “add new team members”

- New robots can be added via “add new robot”

- Select “motorama” to register for this competition

- Select who is going, which robots are going, and register for “parking passes”

- Once the registration is finalized, they will process it and request payment later.

- Once this happens, you must cancel the registration to change it, which means you will likely lose your spots. Contact the event coordinator to make changes.

- Book rental cars and hotels

RoboGames

Website: http://robogames.net/index.php

This is the 120 lb senior competition. Historically 6-8 people have attended this competition. 7 people is the most you can take and rent a single car, but if you have the money, drivers, and robots, you can bring more people. This competition currently fields the sumo, 120 lb, and now the 60lb robot. We also try and bring a 3 lb robot and the freshman who worked on it. Taking 1 or 2 freshman is advised, but they should be selected carefully. This trip is a ton of fun and it could lock in a future leader. Consider shipping robots to reduce carry on weight, but you will need to plan further in advance to make this work. Shipping the robot means it must be done weeks in advance, and SGA money cannot be used.

Going to competition

When leaving for competition, it is your job to make sure everything we need is packed, rides to the airport and campus pickups are arranged, and that every team member knows where they need to be and when they need to be there.

- Make sure every robot has a controller, all tools necessary for assembly, whatever spare parts they have, and a completed robot

- Refer to the packing list on the wiki for tools you should pack

When you are travelling, make sure nobody is alone, and you know where everyone is. It is your job to make sure you make it to the competition venue on time, and that you are checked in and ready to compete.

Monitoring Budget:

Currently, RoboJackets receives money from Student Government Association (SGA), corporate sponsors (Through the ME foundation account) and student dues. SGA allocates money for specific purposes such as “stock material,” “electronics,” etc. Part of your job is preparing a budget proposal to inform the treasurer and president of the amount of money your project will require. A budget proposal is a justification of why and how you want to spend money and a breakdown of where that money is going.

How to write a budget proposal:

- Write a few paragraphs detailing your goals for the year:

- What robots you intend to build

- What competitions you plan on attending

- What you want to accomplish with each robot

- Tabulate how much each robot will spend on various components (This can be as detailed as the current president wants)

- Tabulate Competition and travel costs (includ hotel, plane tickets, and car rentals).

- Compare the planned costs with last year’s costs and be able to justify each expense

- Set each robot’s timeline

[https://docs.google.com/document/d/1AsQ209ePdHW4svBznNipMNucRaU729qJTTXRS09T9i8/edit?usp=sharing] This document is an example, but each proposal should be generated from scratch. You should review the previous year’s spending for a starting point.

Once the president/treasurer has cleared your budget proposal, you are ready to start spending money from approved SGA line items. No money should ever be spent without your knowledge, and it is your responsibility to spend it wisely.

Trusted senior members may be given access to fill out POs for your approval. If they have edit access, they can mark orders ready: make sure anyone with edit access knows the order must be cleared with you first. If there are any budget problems, it is your fault, not whoever is in charge of the robot.

- When buying stock, check multiple sites for the cheapest price. The wiki has a list of suppliers.

- Midwest steel and Al has cheap stock, but it takes time to ship

- Online metals is nice

- McMaster should be reserved for rush orders

- Typically, sheets of stock are more expensive than bars. Either can give you the metal you need.

- Remember to take shipping into account by

- Adding it into the “spent” category once the order has been placed

- Ordering from places where shipping is cheaper

- For some orders, try emailing the vendor and asking for a discount/sponsorship. Please notify the president, VP, or treasurer before reaching out. Sometimes the development office is already in negotiation with a company, and we don’t want to step on their toes.

- If you say you are a student on a robotics team, they will often try to accommodate you. It is important to make it clear we are a student organization, not a research lab. Research labs have money, student orgs don’t. If you want help drafting an email for sponsorship or academic discount, contact the president.

- Watch your metal alloys and plastic types, some are more expensive yet have little performance benefit

- Check what stock and materials we have in the shop. This includes other teams. Sometimes they have spare stock in a thickness they don’t intend on using in the near future

- Make DXF files before ordering waterjet stock to ensure efficient use of material

- Order spare material because there will be mistakes

- Be careful ordering electronics, balancing benefits and tradeoffs is important as prices and specs can vary widely. Again, feel free to consult electrical leads of other teams on any items you and your leader are unsure of.

Sponsors:

As mentioned earlier, many companies will sponsor us with free/discounted products or services. Make sure you keep the treasurer and president informed of sponsors.

Current Sponsors:

- Braddock Metallurgical: heat treatment to harden steel- etc.

- Tim Waters - twaters@braddockmt.com

- Hudson Tool Steel: gave us a discount on steel for Mandiii’s weapon

- Brad Piontkowski - brad@hudsontoolsteel.com

The 3lb Program:

The 3lb program is currently our way of training new members. Each new member of BattleBots joins a “3lb team.” These teams work to build a 3lb robot. The idea is that these robots are cheap, relatively simple, and new members will come out of the program familiar with our build process and machining capability. The teams currently compete at Motorama Robot Conflict. The freshman should do all of the design, CAD and manufacturing.

The 3lb lead and the 3lb council exist to guide the freshman. The 3lb lead acts as the PM for all of the 3lb robots. The 3lb council consists of a few senior members who will mentor the freshmen teams. They will watch the 3lb teams in order to determine if they are on schedule, find who the highest contributing/ most dedicated members are, and provide direction to the new members. Ensure the most dedicated members are engaging in as many learning opportunities as possible. These are the people to which you want to pass knowledge as they are the most likely to pass it on themselves. (They may also point the new members to other senior members if they cannot confidently answer the new member’s question.)

Your job with the 3lb program should be to treat the 3lb lead as one of your robot leads. Depend on the 3lb lead to run the 3lb program, but monitor the program to make sure they are progressing properly, the 3lb members are engaged, and money is being spent properly.

You should work with the 3lb lead to schedule additional work times outside of the Thurs/Fri meetings. It is impossible to finish the robot on time if you are only meeting 2 days/week.

Shop Cleanliness

As an officer within the organization, it is your job to make sure the shop and your space is kept clean and organized. If the shop is messy, your productivity will suffer, sponsors will be put off when they visit, new members will not be impressed, and the other teams will be mad at us.

- Make sure every tool is put away (in its correct location)

- Make sure any machine used is cleaned

- Make sure all of our parts and stock is returned to our shelf

- Make sure the tables and work surfaces are clean

With regards to our shelves, it is your job to make sure they are kept organized. The organizational system is up to you. Make sure every part on the shelf is useful. It is too easy to accumulate clutter. No system can fix having too much stuff.

- Regularly go through the shelf and make sure it is organized

- Throw away useless stuff. Seriously.

- Make sure everything is in its proper place

- Make sure every piece of stock has a planned robot use

- Any stock without a planned use can be moved to general shop stock (which you can later reclaim)

- Make sure electronics on the shelf still function