RC09-KickerChipper

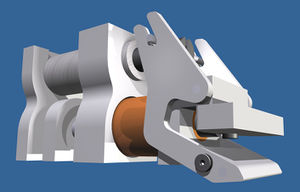

As part of the RoboCup 2010 Mechanical, the kicker provides passing capabilities to the robots. It is part of the chipper / kicker assembly.

Contents

- 1 Related Pages

- 2 Parts & Components

- 2.1 Stock

- 2.1.1 Chipper Solenoid

- 2.1.2 Kicker Solenoid

- 2.1.3 Aluminum Kicker Plunger

- 2.1.4 Kicker Bronze Bushing

- 2.1.5 Chipper Arm Ball Bearing

- 2.1.6 Front Solenoid Mount

- 2.1.7 Middle Solenoid Mount

- 2.1.8 Rear Solenoid Mount

- 2.1.9 Rear Solenoid Mount

- 2.1.10 Plunger Stabilizer

- 2.1.11 Kicker Set Screw

- 2.1.12 Chipper Arm Ball Bearing

- 2.1.13 Chipper Arm Connector

- 2.1 Stock

- 3 Manufacturing and Assembly

- 4 Action Log

Related Pages

Parts & Components

Amounts are based on per robot. Materials are in sizes for prototyping not lowest cost per amount.

Stock

Chipper Solenoid

- Vendor - Solenoid City

- Part No. - S-20-90-24

- Cost - $38.26

- Description - Chipper Solenoid S-20-90-24

Kicker Solenoid

- Vendor - Solenoid City

- Part No. - S-29-150-20HF

- Cost - $93.93

- Description - Kicker Solenoid S-29-150-20HF

Aluminum Kicker Plunger

- Vendor - McMaster-Carr

- Part No. - 8974K25

- Cost - $12.37

- Description - Multipurpose Aluminum (Alloy 6061), 7/16" Diam, 36"

Kicker Bronze Bushing

- Vendor - McMaster-Carr

- Part No. - 6338K462

- Cost - $0.91

- Description - SAE 841 Bronze Flanged-Sleeve Bearing for 7/16" Shaft Diameter, 9/16" OD, 1/2" Length

Chipper Arm Ball Bearing

- Vendor - Grainger

- Part No. - 1ZEH7

- Cost - $7.69

- Description - Mini Ball Bearing,Flanged,Bore 0.1250 In

Front Solenoid Mount

- Vendor - McMaster-Carr

- Part No. - 9008K461

- Cost - $20.35

- Description - Multipurpose Aluminum (Alloy 6061) 1-1/2" Square, 1' Length

Middle Solenoid Mount

- Vendor - McMaster-Carr

- Part No. - 9246K51

- Cost - $36.66

- Description - Multipurpose Aluminum (Alloy 6061) 3/4" Thick, 8" X 8"

Rear Solenoid Mount

- Vendor - McMaster-Carr

- Part No. - 9008K461

- Cost - $20.35

- Description - Multipurpose Aluminum (Alloy 6061) 1-1/2" Square, 1' Length

Rear Solenoid Mount

- Vendor - McMaster-Carr

- Part No. - 9246K21

- Cost - $21.34

- Description - Multipurpose Aluminum (Alloy 6061) 3/8" Thick, 8" X 8"

Plunger Stabilizer

- Vendor - McMaster-Carr

- Part No. - 9246K21

- Cost - $21.34

- Description - Multipurpose Aluminum (Alloy 6061) 3/8" Thick, 8" X 8"

Kicker Set Screw

- Vendor - McMaster-Carr

- Part No. - 91375A196

- Cost - $13.56

- Description - Steel Standard Socket 8-32 x .625"

Chipper Arm Ball Bearing

- Vendor - Grainger

- Part No. - 1ZEH7

- Cost - $7.69

- Description - Mini Ball Bearing,Flanged,Bore 0.1250"

Chipper Arm Connector

- Vendor - McMaster-Carr

- Part No. - 90145A451

- Cost - $11.05

- Description - 18-8 Stainless Steel Dowel Pin 3/32" Diameter, 2" Length

Manufacturing and Assembly

Assembly

Casing is removed from kicker solenoid and bobbin was inserted between the front and middle solenoid mounts

Bronze bushing are inserted into the front and middle solenoid mounts that support the plunger kicker

The plunger kicker is assembled from 7/16" steel and aluminum. The front half of the plunger that is attached to the kicker boot is made of aluminum. It is attached to the steel half of the plunger with an 8-32 5/8" set screw. This allows the plunger to be pulled forward the first half of the stroke without it being pulled back during the second half. Finlay, at the rear of the kicker plunger is the plunger stabilizer, which keeps the kicker from rotating about its long axis and also acts as a mechanical stop to prevent the kicker from shooting out after being fired.

Chipper arms are made to allow room for a wide kicker boot and prevent collision with nearby components. They were placed so that during chipping, the direction of motion of the point on the chipper boot which comes in contact with the ball, moves straight towards the ball's center at the moment of impact. In other words, the direction of motion of the arm at the time of impact is perpendicular with the balls' surface. This ensures that as much energy as possible from chipping goes towards the translational (kinetic) energy of the ball instead of rotational.

The entire assembly is held in place between out top and bottom plate with 1/8" dowel pins and 6-32 1/4" screws which are placed into tops and bottoms of the solenoid mounts.

Machining

Slots for solenoids in solenoid mounts are milled with + .005" tolerance for kicker bobbin and .01" for chipper solenoid. Adding the additional space is especially critical for allowing the chipper solenoid to be put in place. The three solenoid mounts are complex parts that have at least one face milled with a CNC machine while the rest of the features are done manually on a mill.

The kicker plunger was lathed to down a few thousandths of an inch to slide freely inside the bronze bushings. The front of the aluminum half of the plunger is milled so that the kicker boot could be screwed onto it

Chipper arms are cut out using a water jet.

The chipper boot and kicker boot are both entirely milled on a CNC machine

Action Log

- 10/12/2008 - Solenoid inner core diameter for prototype selected.

- 03/04/2009 - Fabrication issues with quality control have been encountered in winding the solenoid.

- 03/13/2009 - Decision has been made to purchase more of last years solenoids and attempt in house modifications.

- 03/22/2009 - Initial concept completed.

- 04/04/2009 - Resizing adjustments made.

- 04/12/2009 - Kicker rev1 design completed.

- 10/25/2009 - First fully machineable chipper design completed. (rev8)

- 01/31/2010 - Prototype kicker and chipper OTS solenoids re selected and designs updated.

- 01/31/2010 - Hardware testing of new electrical mockup shows estimated speeds of 12 m/s with 2008 solenoids.

- 02/02/2010 - New solenoids ordered.

- 02/07/2010 - Chipper & Kicker assemblies updated.

- 03/25/2010 - Chipper variants assembled and tested. Variants non functional.

- 03/26/2010 - Redesign completed, separate test rig designed, and fabrication started.

- 03/27/2010 - Fabrication completed and device tested. Chipper working with a range of up to 13ft. Longer solenoid stroke need for better power transfer.

- 04/04/2010 - Design refinements conducted.