RoboCup: Control Board 2011

| Timeline | |

|---|---|

| Year | 2013 |

| Versions | |

| Control Board | 2011 Rev c |

| Kicker Board | |

| Main Components | |

| MCU | AT91SAM7S256 |

| FPGA | XC3S100E-TQ144 |

| IMU | InvenSense IMU-3000 |

| Motors | Maxon EC45flat 30W |

| Battery | - |

Contents

Overview

This page contains reference information for the 2011c control boards.

Quick Links

Motor Operations

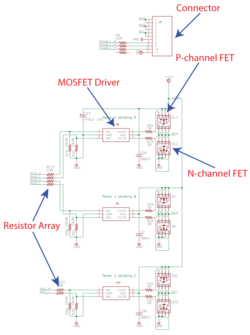

A three-phase bridge (figure 1) is the name of the circuit that is used to control each motor. The control signals for the motors come from the FPGA (XC3S100E). The robot uses 4 30W three phase brushless motors to maneuver itself on the field. A 5th motor is also used for the dribbler. In order to operate each motor with the needed precision, a brushless motor driving circuit is used for every motor. The motors also contain hall- Each phase of a brushless motor is controlled using 2 transistors. For this application, a MOSFET type transistor is used. Although MOSFET is the appropriate technical name, it is often shortened by simply saying FET. A p-channel MOSFET (IRF9310TRPBF) is used to connect to +12V and a n-

MOSFET Operation

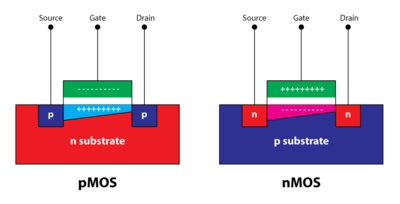

A MOSFET or Metal-Oxide-Semiconductor Field-Effect Transistor, is basically a switch. There are 3 terminals: source, drain, and gate, and figure 2 outlines the physical layout of their relations. If you apply a voltage at the gate, this will allow a flow of charges from the source to the drain. These devices use metal oxides and the charges flow due to the effect of an electric field between the source and drain. Hence why they are called MOSFET. There are 2 types of MOSFETs, nMOSFET - where the majority of charge carriers are electrons - and pMOSFET - where the majority of charge carriers are holes. The gate-source voltage must be high (positive) to turn on a nMOS and low (negative) to turn on a pMOS. This voltage is refereed to as the threshold voltage and is defined in table 1 below. The pMOS is better at pulling the output high while nMOS is better at pulling the output low; Therefore, both MOSFETs are used in the motor driver circuit - they complement one another.

| nMOS | pMOS |

|---|---|

Single Motor Winding Circuit Explanation

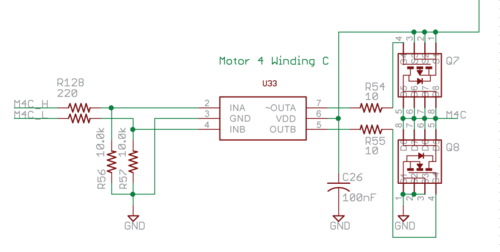

From figure 3, OUTA is the inverting output and OUTB is non-inverting output (from the MOSFET Driver). Q7 is the pMOS and Q8 is the nMOS. The source of the pMOS is connected to VDD (+12V) and the drain is connected to one of the motor coils. In the nMOS, the source is connected to the motor coil while the drain is connected to GND.

-down resistors that ensure INA and INB maintain a proper value if there is no signal from the FPGA. R54 and R55 provide signal stability for the base of each FET (the voltage could oscillate back and forth without them). C26 is used to filter out unwanted high frequencies from VDD.

Debugging

If a fuse is blown, then a likely cause is that one of the FETs experienced a high back flow of current and broke. Ideally you should test for faulty FETs with the FET tester. If you are stranded on a deserted island without the FET tester, you can still determine if a FET is faulty or not. The steps for checking both nFETs and pFETs using a digital multimeter are outlined on the testing a MOSFET page. It is recommended to change the entire three-phase bridge (3 pFETs, 3 nFETs and 3 MOSFET drivers) if any 1 part is damaged.

Other Websites/Resources

- Youtube video explaining the operations of brushless DC motors (BLDC) - [1]

- PDF about more BLDC motors - [2]

Power Operations

This is the main stage where the input, VDD, from the battery is converted to the different DC voltage levels required by the various components on the board. To protect the components on the board, 2 things are done:

- The kicker's power supply is separated from the rest of the control board.

- A fuse is used for the kicker power supply and the power supply for the rest of the board.

The big, red 10A fuse is for the kicker power supply and goes to the kicker board and the motor driver circuit. As a safety measure, a separate fuse is used on the kicker board as soon as the power supply comes in from the control board.

Voltage Monitor for kicker

The voltage monitor is a circuit used to measure the voltage at the output of the transformers, since they are in the range of 150V and is a cause of concern for safety if it is exceeded. The main component of the voltage monitor is the analog-to-digital converter, ADC081C027. The type of architecture used in the ADC is an 8-bit Successive Approximation Register (SAR). In successive approximation, the ADC internally has a DAC, a comparator and 8-

LM2734

The LM2734 is a voltage converter that can convert a maximum of 24VDC to different output voltages depending upon how the other pins are connected to the each other and the value of connected passive components. The circuit used to convert VDD to 5V is based on a similar circuit provided in the datasheet. The output voltage depends on the biasing values of the resistors R83 and R84 at the feedback (FB) pin. From the reference diagram, the way to calculate output voltage is given by, R1=(Vo/Vref- Usually, R2 is fixed as 10k?. We need VO to be 5V. Vref is set internally in the IC as 0.8V, so R1 is calculated to be 52.5k?. This is what has been used in the control board circuit.

MCP1824T

The circuit with these ICs are pretty straight forward. They accept a maximum input of 6V and then give a fixed output voltage. The name of the IC denotes the value of the output voltage. For example, in MCP1824ST---1202E/OT gives a 1.2VDC output and MCP1824T-2502E/OT gives a 2.5VDC output.

Debugging

- LM2734

- The voltage at the output should be approximately 5V.

- The voltage at the FB pin should be approximately 4.2V.

- The input voltage should not exceed 24VDC.

- MCP1824T

- The input and output voltages should be at a constant value as specified by the schematic. If there is at least a 0.5VDC difference, then it could cause many electrical faults.

Radio Operations

More information to be added

| Antenna board |

Images of Control Board

**Images will be integrated into the page when uploading the files is stable. Until then, there is a PDF download.

Download the images as a PDF file.

- RC EE control board 2011c 001.jpg

placeholder image

- RC EE control board 2011c 002.jpg

placeholder image

- RC EE control board 2011c 003.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

- RC - control board 2011c - back - 001.jpg

placeholder image

Board Overview Videos

| Board Overview | |

| FPGA Integration |

Component List

PDF Download

Sortable Table

**Clink any heading to sort the table rows**