Difference between revisions of "RC09-Omni"

Jump to navigation

Jump to search

| (18 intermediate revisions by 5 users not shown) | |||

| Line 3: | Line 3: | ||

==Drawings== | ==Drawings== | ||

| − | + | [[Image:OmniWheel_Explosion.jpg|400px]] | |

| − | |||

==Assembly Structure== | ==Assembly Structure== | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | |||

==Parts & Components== | ==Parts & Components== | ||

| Line 68: | Line 60: | ||

:Description - Neoprene O-Ring AS568A Dash Number 012 | :Description - Neoprene O-Ring AS568A Dash Number 012 | ||

| − | == | + | ==Assembly== |

| − | ==== | + | ====Tools needed==== |

| − | : | + | :3 axis CNC Mill |

| − | : | + | :WaterJet |

| − | + | :Hex Keys | |

| − | ===== | + | :Press |

| − | + | :CNC Lathe(parts are outsourced) | |

| − | + | ====Instructions==== | |

| − | ===== | + | =====Fabrication===== |

| − | + | #The Omni body is fabricated through the use of the HAAS a 3 axis CNC Mill. The 3/8'' plate is used for this process | |

| + | #The Omni Plate or Wheel plate is made with the Waterjet using the .063'' 7075 aluminum sheet. | ||

| + | ##Due to the Omni Plates being quite small it is advised that you connect at least 2 together and then grinding away the small connection. | ||

| + | #The omni rollers are outsourced. If one has access to a CNC lathe then one could fabricate one's own. | ||

| + | #The planetary gear is also outsourced. | ||

| + | =====Assembly===== | ||

| + | # Put o-rings in the groove in the rollers and press the 1/16'' dowel pins into the hole. | ||

| + | # Use the press to press the bearing into the center hole of the omni body and the dowel pins into the 3 holes surrounding it. | ||

| + | # On the back of the omni body place the plastic inserts into the small holes. | ||

| + | # Attach the planetary gear by screwing in the 0-80 screws into the plastic inserts. | ||

| + | # Place rollers with o-rings and dowel pins into the grooves on the omni body | ||

| + | # Fit plate on top of the omni body and secure it by screwing in the 6-32x1/4 screws. | ||

==Cost Estimates== | ==Cost Estimates== | ||

| Line 102: | Line 105: | ||

# 04/03/2010 - First fleet omni body made. Process is down to 2hrs. | # 04/03/2010 - First fleet omni body made. Process is down to 2hrs. | ||

| − | [[Category: | + | [[Category: RC Mechanical]] |

| + | [[Category:2008-2009]] | ||

Latest revision as of 19:51, 24 May 2020

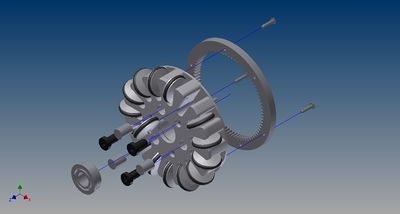

As part of the RoboCup 2009 Mechanical, the Omni Wheels allow the robots to move in any direction at anytime.

Contents

Drawings

Assembly Structure

Parts & Components

Amounts are based on per robot. Materials are in sizes for prototyping not lowest cost per robot volume pricing if available is in parenthesis.

Stock

Plate - Wheel Plate

- Vendor - McMaster-Carr

- Part No. - 8885K13

- Cost - $21.63

- Description - Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12"

Plate - Wheel Body

- Vendor - McMaster-Carr

- Part No. - 9246K23

- Cost - $28.51

- Description - Multipurpose Aluminum (Alloy 6061) 3/8" Thick, 12" X 12"

Shaft - Rollers

- Vendor - McMaster-Carr

- Part No. - 9063K243

- Cost - $17.48

- Description - Alloy 7075 Aluminum Precision Ground Rod 1/8" Diameter, 3' Length

- Note: Usually ships within 2 weeks.

Fasteners

6-32 Low Head Socket Cap Screw

- Vendor - McMaster-Carr

- Part No. - 92220A141

- Cost - $7.42 (packs of 25)

- Description - Alloy Steel Low Head Socket Cap Screw 6-32 Thread, 1/4" Length

3/16" Dowel Pin

- Vendor - MSC

- Part No. - 88231758

- Cost - $43.08 (per 100)

- Description - Precision Ground Dowel Pins - Stainless Steel Type: Dowel Pin Diameter: 3/16 Overall Length: 1/4 Material: Stainless Steel - 416 SS Finish/Coating: Bright

1/16" Dowel Pin

- Vendor - MSC

- Part No. - 88231196

- Cost - $19.83 (per 100)

- Description - Precision Ground Dowel Pins - Stainless Steel Type: Dowel Pin Diameter: 1/16 Overall Length: 1/4 Material: Stainless Steel - 416 SS Finish/Coating: Bright

Other

O-Ring

- Vendor - McMaster-Carr

- Part No. - 94115K012

- Cost - $2.87 (Pks of 100)

- Quantity -

- Description - Neoprene O-Ring AS568A Dash Number 012

Assembly

Tools needed

- 3 axis CNC Mill

- WaterJet

- Hex Keys

- Press

- CNC Lathe(parts are outsourced)

Instructions

Fabrication

- The Omni body is fabricated through the use of the HAAS a 3 axis CNC Mill. The 3/8 plate is used for this process

- The Omni Plate or Wheel plate is made with the Waterjet using the .063 7075 aluminum sheet.

- Due to the Omni Plates being quite small it is advised that you connect at least 2 together and then grinding away the small connection.

- The omni rollers are outsourced. If one has access to a CNC lathe then one could fabricate one's own.

- The planetary gear is also outsourced.

Assembly

- Put o-rings in the groove in the rollers and press the 1/16 dowel pins into the hole.

- Use the press to press the bearing into the center hole of the omni body and the dowel pins into the 3 holes surrounding it.

- On the back of the omni body place the plastic inserts into the small holes.

- Attach the planetary gear by screwing in the 0-80 screws into the plastic inserts.

- Place rollers with o-rings and dowel pins into the grooves on the omni body

- Fit plate on top of the omni body and secure it by screwing in the 6-32x1/4 screws.

Cost Estimates

Action Log

- 10/19/2008 - Initial revised roller design completed.

- 11/02/2008 - Added new groove style for new rollers.

- 11/09/2008 - Refined roller design.

- 12/30/2008 - Resized to match internal gear dimensions.

- 01/13/2009 - Added fillets.

- 02/01/2009 - Drawing for rollers produced and ready to be posted for quote.

- 02/22/2009 - Design for prototype completed.

- 03/15/2009 - Rollers posted to mfg.com for quote.

- 03/17/2009 - Design revised. Internal gear added to omni body.

- 03/25/2009 - Supplier for rollers selected.

- 04/08/2009 - All 400 Rollers arrive for omni wheels.

- 05/05/2009 - 1/2 of rollers are assembled.

- 07/18/2009 - Omni bodies CAM'd.

- 01/26/2010 - Omni plates for prototype water jetted.

- 02/03/2010 - Tooling required to make omni bodies arrives.

- 02/13/2010 - First omni body completed. Problems encountered with automated tapping of 6-32s.

- 03/20/2010 - Last omni body for prototype made.

- 03/23/2010 - Revisions made to omni design to allow for better draining of retaining compound, symmetrical plate positioning, and new bearings.

- 04/03/2010 - First fleet omni body made. Process is down to 2hrs.