Difference between revisions of "RC09-DriveModule"

Jump to navigation

Jump to search

(→Action Log) |

|||

| (54 intermediate revisions by 4 users not shown) | |||

| Line 4: | Line 4: | ||

==Assembly Structure== | ==Assembly Structure== | ||

| + | ====Parts Structure==== | ||

| + | # Inner Drive Plate | ||

| + | # Omni Wheel | ||

| + | # Output Axel | ||

| + | # Spindle | ||

| + | ## Internal Gear | ||

| + | ## Bearing Plate | ||

| + | ## Wheel Attachment Plate | ||

| + | ## Hex Shaft | ||

| + | |||

| + | |||

====Parts List==== | ====Parts List==== | ||

| + | # 1 - Omni Wheel (RC-2009-02-00) | ||

| + | # 1 - Maxon Brushless Drive Motor (RC-2009-03-01) | ||

| + | # 1 - Drive Module Plate (RC-2009-03-02) | ||

| + | # 1 - Shaft (RC-2009-03-03) | ||

| + | # 1 - Internal Gear (RC-2009-03-04) | ||

| + | # 3 - 5/8" Long Hex Standoffs (RC-2009- -) | ||

| + | # 2 - 1/4" Ball Bearings (RC-2009-03-05) (RC-2008-03-08) | ||

====Instructions==== | ====Instructions==== | ||

==Parts & Components== | ==Parts & Components== | ||

| + | ===Motors and Encoders=== | ||

| + | ====Brushless Motors==== | ||

| + | :Vendor - Maxon | ||

| + | :Part No. - 200142 | ||

| + | :Cost - $50.53(EUR) | ||

| + | :Description - EC 45 flat Ø45 mm, brushless, 30 Watt | ||

| + | |||

| + | ====Encoders==== | ||

| + | :Vendor - US Digital | ||

| + | :Part No. - E4P-360-118-N-S-D-T-B | ||

| + | :Cost - $24.81 | ||

| + | :Description - E4P OEM Miniature Optical Kit Encoder [http://usdigital.com/assets/drawings/471.pdf Spec] | ||

| + | :Note - Vendor supplied 3-48 x 1/4" screws are not long enough for 0.05" plate. We have switched to transfer adhesive. | ||

| + | |||

===Gears & Bearings=== | ===Gears & Bearings=== | ||

====Motor Output Gear==== | ====Motor Output Gear==== | ||

| Line 16: | Line 48: | ||

:Description - Module 0.5, 16 Teeth, 20° Pressure Angle, 303 Stainless Steel Gear | :Description - Module 0.5, 16 Teeth, 20° Pressure Angle, 303 Stainless Steel Gear | ||

| − | ==== | + | ====Internal Gear (Standard)(Supplier A)==== |

| − | : | + | :Vendor - SDP/SI |

| + | :Part No. - S1E62Z-072S110 | ||

| + | :Cost - $47.16 ($44.51) | ||

| + | :Description - 72 DP, 110T, AGMA Q10, 303 STAINLESS STEEL INTERNAL GEAR | ||

| − | ==== | + | ====Internal Gear (Standard)(Supplier B)==== |

| − | : | + | :Vendor - WM BERG |

| + | :Part No. - N72S2-110 | ||

| + | :Cost - $46.25 | ||

| + | :Description - 72 DP, 110T, AGMA Q10, 303 STAINLESS STEEL INTERNAL GEAR | ||

| − | ====Internal Gear==== | + | ====Internal Gear (Metric)(Supplier A)==== |

| − | :Vendor - SDP/SI | + | :Vendor - SDP/SI |

| − | :Part No. - S1E05ZM05S072 | + | :Part No. - S1E05ZM05S072 |

| − | :Cost - $31.10 ($28.48) | + | :Cost - $31.10 ($28.48) |

:Description - Module 0.5, 72 TEETH, 20° Pressure Angle, 303 Stainless Steel, INTERNAL GEAR | :Description - Module 0.5, 72 TEETH, 20° Pressure Angle, 303 Stainless Steel, INTERNAL GEAR | ||

| + | |||

| + | ====Internal Gear (Metric)(Supplier B)==== | ||

| + | :Vendor - | ||

| + | :Part No. - | ||

| + | :Cost - | ||

| + | :Description - | ||

| + | |||

====Bearing (1/4" Shaft)==== | ====Bearing (1/4" Shaft)==== | ||

:Vendor - Grainger | :Vendor - Grainger | ||

| Line 41: | Line 86: | ||

:Description - Alloy 6061 Aluminum Sheet .125" Thick, 12" X 12" | :Description - Alloy 6061 Aluminum Sheet .125" Thick, 12" X 12" | ||

| − | ====Al Plate 0. | + | ====Al Plate 0.05"==== |

:Vendor - McMaster-Carr | :Vendor - McMaster-Carr | ||

| − | :Part No. - | + | :Part No. - 8885K18 |

| − | :Cost - $ | + | :Cost - $35.62 Each |

| − | :Description - Alloy | + | :Description - Alloy 7075 Aluminum Sheet .050" Thick, 12" X 24" |

| + | :Note - 7075 b/c we have left over from last year other wise 6061. | ||

===Fasteners=== | ===Fasteners=== | ||

| + | ====0-80 x 1/4" Button Head==== | ||

| + | :Vendor - McMaster-Carr | ||

| + | :Part No. - 92949A054 | ||

| + | :Cost - $9.30 (Packs of 50) | ||

| + | :Description - 18-8 SS Button Head Socket Cap Screw 0-80 Thread, 1/4" Length | ||

| + | |||

====6-32 Low Head Socket Cap Screw==== | ====6-32 Low Head Socket Cap Screw==== | ||

:Vendor - McMaster-Carr | :Vendor - McMaster-Carr | ||

| Line 53: | Line 105: | ||

:Cost - $7.42 (Packs of 25) | :Cost - $7.42 (Packs of 25) | ||

:Description - Alloy Steel Low Head Socket Cap Screw 6-32 Thread, 1/4" Length | :Description - Alloy Steel Low Head Socket Cap Screw 6-32 Thread, 1/4" Length | ||

| + | |||

| + | ====6-32 Socket Cap Counter Sunk Screw==== | ||

| + | :Vendor - McMaster-Carr | ||

| + | :Part No. - 91253A144 | ||

| + | :Cost - $9.91 (Packs of 100) | ||

| + | :Description - Alloy Steel Flat Head Socket Cap Screw 6-32 Thread, 1/4" Length, Black Oxide | ||

| + | |||

| + | ====6-32 Button Head==== | ||

| + | :Vendor - McMaster-Carr | ||

| + | :Part No. - 92949A143 | ||

| + | :Cost - $7.88 (Packs of 100) | ||

| + | :Description - 18-8 SS Button Head Socket Cap Screw 6-32 Thread, 3/16" Length | ||

| + | |||

| + | ====6-32 3/4" Standoffs==== | ||

| + | :Vendor - Digi-Key | ||

| + | :Part No. - 2211K-ND | ||

| + | :Cost - $6.14 (pk 10) $55.83 (pk 100) | ||

| + | :Description - STANDOFF HEX 6-32THR ALUM .750" | ||

| + | |||

| + | ====10-32 Shoulder Bolt==== | ||

| + | :Vendor - McMaster-Carr | ||

| + | :Part No. - 94035A531 | ||

| + | :Cost - $2.08 (each) | ||

| + | :Description - 18-8 SS Precision Hex Socket Shoulder Screw 1/4" Shoulder Dia, 1/8" L Shoulder, 10-32 Thread | ||

====M3 x 6 Metric Flat Head Socket Cap Screw==== | ====M3 x 6 Metric Flat Head Socket Cap Screw==== | ||

| Line 62: | Line 138: | ||

==== 1/16" Locating Pins==== | ==== 1/16" Locating Pins==== | ||

:Vendor - MSC Industrial Supply | :Vendor - MSC Industrial Supply | ||

| − | :Part No. - | + | :Part No. - 88231196 |

| − | :Cost - $ | + | :Cost - $19.83 (pk 100) |

| − | :Description - Precision Ground Dowel Pins - | + | :Description - Precision Ground Dowel Pins - Stainless Steel Type: Dowel Pin Diameter: 1/16 Overall Length: 1/4 Material: Stainless Steel - 416 SS Finish/Coating: Bright |

| + | |||

| + | ==== 1/8" Locating Pins==== | ||

| + | :Vendor - MSC Industrial Supply | ||

| + | :Part No. - 88231469 | ||

| + | :Cost - $26.46 (pk 100) | ||

| + | :Description - Precision Ground Dowel Pins - Stainless Steel Type: Dowel Pin Diameter: 1/8 Overall Length: 3/16 Material: Stainless Steel - 416 SS Finish/Coating: Bright | ||

| + | |||

| + | ==Fabrication== | ||

==Action Log== | ==Action Log== | ||

| Line 72: | Line 156: | ||

# 01/12/2009 - Dropped 8-32 screws to 6-32, and made treading full on hex.. | # 01/12/2009 - Dropped 8-32 screws to 6-32, and made treading full on hex.. | ||

# 01/13/2009 - Confirmed that Maxon does offer custom shafts for motors and added current materials to wiki. | # 01/13/2009 - Confirmed that Maxon does offer custom shafts for motors and added current materials to wiki. | ||

| + | # 01/25/2009 - Preliminary encoder selected. | ||

| + | # 01/26/2009 - Initial design with a encoder completed. | ||

| + | # 02/02/2009 - Design revised. Attachment to bottom plate enhanced and encoder fully compensated for. | ||

| + | # 02/22/2009 - Design for prototype completed. | ||

| + | # 03/07/2009 - Design revised. Drive modules reshaped to accommodate capacitors. | ||

| + | # 03/16/2009 - Gear posted to mfg.com for quote. | ||

| + | # 03/17/2009 - Design revised. Spindle removed and internal gear placed on omni body. | ||

| + | # 03/19/2009 - Plates reshaped to allow room for dribbler components. | ||

| + | # 03/17/2009 - RFQ for internal gears posted on mfg.com. | ||

| + | # 03/25/2009 - Supplier for initial run of internal gears selected. | ||

| + | # 03/26/2009 - Have moved to reversing engineering and modifying drive motors in house. | ||

| + | # 04/01/2009 - A spare drive motor from 2008 fleet was successfully disassembled and reassembled. | ||

| + | # 04/02/2009 - Design of fixture for reassembling drive motors completed. Info can be found on the [[RC09-DriveMotorFab | Drive Motor Fixture]] page. | ||

| + | # 07/18/2009 - Drive plates have been CAM'd. | ||

| + | # 07/28/2009 - Motor shaft modified to allow for better assembly. | ||

| + | # 10/18/2009 - Encoder plate CAM'd up in waterjet software. | ||

| + | # 11/01/2009 - Output shaft standoffs fabricated. | ||

| + | # 12/23/2009 - Drive plates machined. | ||

| + | # 01/26/2010 - Encoder plates water jetted. | ||

| + | # 02/16/2010 - Drive module assembled and wheel wobble discovered. | ||

| + | # 03/19/2010 - Output shafts modified and remade. | ||

| + | # 03/20/2010 - All drive modules assembled and tested wheel wobble still persists. | ||

| + | # 03/25/2010 - New shielded bearings arrive and installed. Wheel wobble has been mitigated. | ||

| + | # 03/27/2010 - Drive modules now ready fleet. | ||

| − | [[Category: | + | [[Category: RC Mechanical]] |

| + | [[Category:2008-2009]] | ||

Latest revision as of 19:51, 24 May 2020

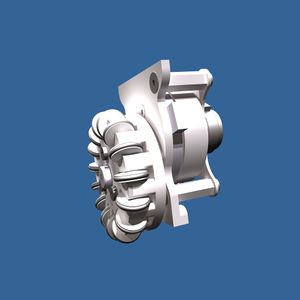

As part of the RoboCup 2009 Mechanical, Drive Modules integrate the motor, gearbox and omniwheel in to one modular assembly.

Contents

Assembly Structure

Parts Structure

- Inner Drive Plate

- Omni Wheel

- Output Axel

- Spindle

- Internal Gear

- Bearing Plate

- Wheel Attachment Plate

- Hex Shaft

Parts List

- 1 - Omni Wheel (RC-2009-02-00)

- 1 - Maxon Brushless Drive Motor (RC-2009-03-01)

- 1 - Drive Module Plate (RC-2009-03-02)

- 1 - Shaft (RC-2009-03-03)

- 1 - Internal Gear (RC-2009-03-04)

- 3 - 5/8" Long Hex Standoffs (RC-2009- -)

- 2 - 1/4" Ball Bearings (RC-2009-03-05) (RC-2008-03-08)

Instructions

Parts & Components

Motors and Encoders

Brushless Motors

- Vendor - Maxon

- Part No. - 200142

- Cost - $50.53(EUR)

- Description - EC 45 flat Ø45 mm, brushless, 30 Watt

Encoders

- Vendor - US Digital

- Part No. - E4P-360-118-N-S-D-T-B

- Cost - $24.81

- Description - E4P OEM Miniature Optical Kit Encoder Spec

- Note - Vendor supplied 3-48 x 1/4" screws are not long enough for 0.05" plate. We have switched to transfer adhesive.

Gears & Bearings

Motor Output Gear

- Vendor - SDP/SI

- Part No. - S1VS05M016F0704

- Cost - $22.06 ($18.16)

- Description - Module 0.5, 16 Teeth, 20° Pressure Angle, 303 Stainless Steel Gear

Internal Gear (Standard)(Supplier A)

- Vendor - SDP/SI

- Part No. - S1E62Z-072S110

- Cost - $47.16 ($44.51)

- Description - 72 DP, 110T, AGMA Q10, 303 STAINLESS STEEL INTERNAL GEAR

Internal Gear (Standard)(Supplier B)

- Vendor - WM BERG

- Part No. - N72S2-110

- Cost - $46.25

- Description - 72 DP, 110T, AGMA Q10, 303 STAINLESS STEEL INTERNAL GEAR

Internal Gear (Metric)(Supplier A)

- Vendor - SDP/SI

- Part No. - S1E05ZM05S072

- Cost - $31.10 ($28.48)

- Description - Module 0.5, 72 TEETH, 20° Pressure Angle, 303 Stainless Steel, INTERNAL GEAR

Internal Gear (Metric)(Supplier B)

- Vendor -

- Part No. -

- Cost -

- Description -

Bearing (1/4" Shaft)

- Vendor - Grainger

- Part No. - 1ZEJ7

- Cost - $5.59 Each

- Description - Miniature Ball Bearing, Open, Flanged, Bore Dia 0.2500 In, Outside Dia 0.5000 In, Width 0.1250 In, Flange Dia 0.5470 In, Flange Thickness 0.0230 In, ABEC Level 3

- Info - Web Link

Stock

Al Plate 1/8"

- Vendor - McMaster-Carr

- Part No. - 89015K18

- Cost - $26.06

- Description - Alloy 6061 Aluminum Sheet .125" Thick, 12" X 12"

Al Plate 0.05"

- Vendor - McMaster-Carr

- Part No. - 8885K18

- Cost - $35.62 Each

- Description - Alloy 7075 Aluminum Sheet .050" Thick, 12" X 24"

- Note - 7075 b/c we have left over from last year other wise 6061.

Fasteners

0-80 x 1/4" Button Head

- Vendor - McMaster-Carr

- Part No. - 92949A054

- Cost - $9.30 (Packs of 50)

- Description - 18-8 SS Button Head Socket Cap Screw 0-80 Thread, 1/4" Length

6-32 Low Head Socket Cap Screw

- Vendor - McMaster-Carr

- Part No. - 92220A141

- Cost - $7.42 (Packs of 25)

- Description - Alloy Steel Low Head Socket Cap Screw 6-32 Thread, 1/4" Length

6-32 Socket Cap Counter Sunk Screw

- Vendor - McMaster-Carr

- Part No. - 91253A144

- Cost - $9.91 (Packs of 100)

- Description - Alloy Steel Flat Head Socket Cap Screw 6-32 Thread, 1/4" Length, Black Oxide

6-32 Button Head

- Vendor - McMaster-Carr

- Part No. - 92949A143

- Cost - $7.88 (Packs of 100)

- Description - 18-8 SS Button Head Socket Cap Screw 6-32 Thread, 3/16" Length

6-32 3/4" Standoffs

- Vendor - Digi-Key

- Part No. - 2211K-ND

- Cost - $6.14 (pk 10) $55.83 (pk 100)

- Description - STANDOFF HEX 6-32THR ALUM .750"

10-32 Shoulder Bolt

- Vendor - McMaster-Carr

- Part No. - 94035A531

- Cost - $2.08 (each)

- Description - 18-8 SS Precision Hex Socket Shoulder Screw 1/4" Shoulder Dia, 1/8" L Shoulder, 10-32 Thread

M3 x 6 Metric Flat Head Socket Cap Screw

- Vendor - McMaster-Carr

- Part No. - 91294A126

- Cost - $6.76 (pk 100)

- Description - Metric Flat Head Socket Cap Screw Class 10.9 Stl, M3 Size, 6mm Length, .50mm Pitch (Needs 90 deg countersink)

1/16" Locating Pins

- Vendor - MSC Industrial Supply

- Part No. - 88231196

- Cost - $19.83 (pk 100)

- Description - Precision Ground Dowel Pins - Stainless Steel Type: Dowel Pin Diameter: 1/16 Overall Length: 1/4 Material: Stainless Steel - 416 SS Finish/Coating: Bright

1/8" Locating Pins

- Vendor - MSC Industrial Supply

- Part No. - 88231469

- Cost - $26.46 (pk 100)

- Description - Precision Ground Dowel Pins - Stainless Steel Type: Dowel Pin Diameter: 1/8 Overall Length: 3/16 Material: Stainless Steel - 416 SS Finish/Coating: Bright

Fabrication

Action Log

- 12/29/2008 - Internal gears selected.

- 12/30/2008 - Initial design of gear box completed.

- 01/11/2009 - Removed mass and moved to 1/8" plate for motor mounting.

- 01/12/2009 - Dropped 8-32 screws to 6-32, and made treading full on hex..

- 01/13/2009 - Confirmed that Maxon does offer custom shafts for motors and added current materials to wiki.

- 01/25/2009 - Preliminary encoder selected.

- 01/26/2009 - Initial design with a encoder completed.

- 02/02/2009 - Design revised. Attachment to bottom plate enhanced and encoder fully compensated for.

- 02/22/2009 - Design for prototype completed.

- 03/07/2009 - Design revised. Drive modules reshaped to accommodate capacitors.

- 03/16/2009 - Gear posted to mfg.com for quote.

- 03/17/2009 - Design revised. Spindle removed and internal gear placed on omni body.

- 03/19/2009 - Plates reshaped to allow room for dribbler components.

- 03/17/2009 - RFQ for internal gears posted on mfg.com.

- 03/25/2009 - Supplier for initial run of internal gears selected.

- 03/26/2009 - Have moved to reversing engineering and modifying drive motors in house.

- 04/01/2009 - A spare drive motor from 2008 fleet was successfully disassembled and reassembled.

- 04/02/2009 - Design of fixture for reassembling drive motors completed. Info can be found on the Drive Motor Fixture page.

- 07/18/2009 - Drive plates have been CAM'd.

- 07/28/2009 - Motor shaft modified to allow for better assembly.

- 10/18/2009 - Encoder plate CAM'd up in waterjet software.

- 11/01/2009 - Output shaft standoffs fabricated.

- 12/23/2009 - Drive plates machined.

- 01/26/2010 - Encoder plates water jetted.

- 02/16/2010 - Drive module assembled and wheel wobble discovered.

- 03/19/2010 - Output shafts modified and remade.

- 03/20/2010 - All drive modules assembled and tested wheel wobble still persists.

- 03/25/2010 - New shielded bearings arrive and installed. Wheel wobble has been mitigated.

- 03/27/2010 - Drive modules now ready fleet.