Difference between revisions of "RC08Brushless"

(→Parts) |

(→Schematics) |

||

| Line 40: | Line 40: | ||

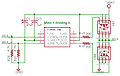

==Schematics== | ==Schematics== | ||

| − | + | <gallery> | |

| + | Image:RC_mot_drvr_08.jpg|Brushless Motor Driver Schematic | ||

| + | </gallery> | ||

| + | |||

==Parts== | ==Parts== | ||

We are performing commutation on the FPGA with gate drivers. | We are performing commutation on the FPGA with gate drivers. | ||

Revision as of 12:44, 23 January 2008

In 2008 RoboCup switched to brushless DC motors. While brushless motors are smaller and far more efficient than brushed motors the commutation normally performed inside a brushed DC motor will need to be done externally using some control circuitry. There are two main parts to our brushless motor controller solution; the controller which uses sensors on the motor to gate signals to one of three coils, and the half-bridge motor drivers which actually drive the coils.For the controller a special-purpose brushless motor driver IC was used. For information on the motors or motor control software please see their respective pages.

Contents

Motor Frequency Analysis

Tasks

- [ ] Get the motor and begin playing with it

- [X] Call Maxon and get a recommendation on motor drivers (They spec parts not sure which drivers they use)

- [X] Figure out max current draw. (10A starting current)

- [ ] Develope Model of Motor and get Frequency Response

- [ ] Find and purchase Flat Flex Cable (FFC) connectors

- [ ] Purchase large mosfets for testing

- [ ] Purchase Surfboard for mounting DSC

- [ ] Build test rig

- [ ] Finalize on a DSC

- [ ] Choose MOSFETS

- [ ] Sample all the parts

- [ ] Schematic Design

- [ ] Build prototype

- [ ] Prototype evaluation

- [ ] Make necessary changes

Specifications

Motor Controller Chip

- The motor is spec'd at 12V and is 30W

- A decent transient response (dead-time + switching time)

- 3-Channels in one package

- Braking is not a requirement but would be nice

- High Impedance OFF state

- Fault protection (overvoltage, overcurrent, fast response)

- Small package

- Ability to operate in the >20kHz range

- Gate drive capability (either can directly driver the gate or is open drain.)

- Data sheet recommends a MOSFET

- Matrix of Potential Drivers

MOSFET

- NMOS and a PMOS

- The FETS have to be able to handle 10A drain current

- Matrix of Potential FETS Other FETs we considered

Schematics

Parts

We are performing commutation on the FPGA with gate drivers.

Gate Driver

Microchip TC4428

- 1.5 A

- 6 mA quiescent

- Noninverting low side

- Inverting high side

FETS

| Part No. | Make | Package | ContIDS | MaxIDS | Rds | MaxVGS | Samples | Data Sheet |

|---|---|---|---|---|---|---|---|---|

| NTMS4503N N-Channel | ON Semi | SO-8 | 14 A | -- | -- | 28 V | Y | [1] |

| NTMS10P02 P-Channel | ON Semi | SO-8 | 10 A | -- | -- | 20 V | Y | [2] |

Motor Connector

Hirose FH12-11S-1SH 11 position 1 mm pitch

Articles

Modeling a DC motor Brush-Less Motor Simulink

Links

- Electrical System

- Motor Datasheet: Media:07_197_e.pdf