Difference between revisions of "Maori Design Guide"

Tjackson86 (talk | contribs) (→Overview) |

(→Design Decisions) |

||

| Line 57: | Line 57: | ||

==== Design Decisions ==== | ==== Design Decisions ==== | ||

| − | + | Beater Bar | |

| + | * Material: S7 Tool Steel | ||

| + | * Profile: prioritized compatibility for EDM | ||

| + | ** constant cross-section | ||

| + | ** axisymmetric to avoid vibration induced by skewed center of mass | ||

| + | |||

| + | Hubs | ||

| + | * Material: Aluminum 6061-T6 | ||

| + | ** machined in house, so ease of machining outweighed material selection | ||

| + | ** the brunt of forces are received by the beater bar and chassis, this material selection allows | ||

| + | deformation of hubs before the beater bar and chassis, which took longer to machine | ||

| + | * Shape: | ||

==== Calculations ==== | ==== Calculations ==== | ||

Revision as of 18:33, 11 April 2020

Contents

Introduction

test

Design Basics

Chassis

Overview

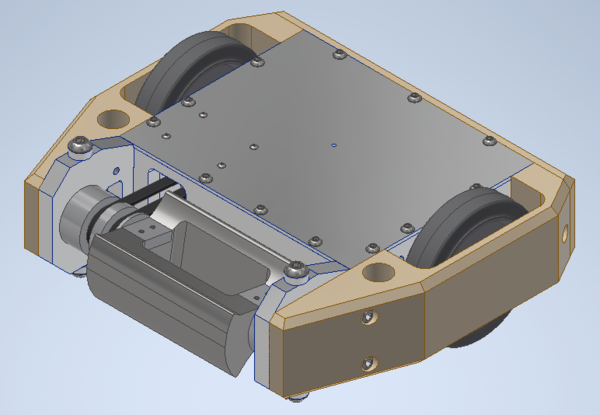

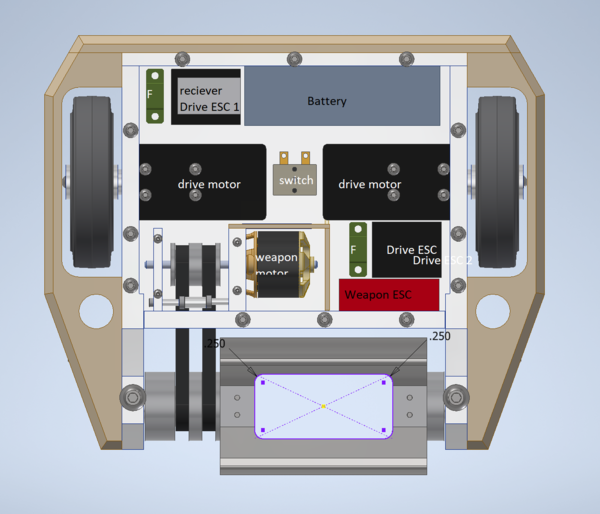

Maori's chassis consists of six parts: A top, bottom, front, and back plate as well as two side plates. All of these components are made from 6061 Aluminum. The side plates provide thicker support towards the weapon, while allowing skids to be inserted. Maori's drive modules also fit into the side plates. The front plate allows for belt access between the interior of the robot and the weapon pulley. It also fits into the side plates The bottom and top plates provide slots for interior plastic guards and bolt into the rest of the chassis.

Design Decisions

test

- Notes/Helpful Advice

- test

Armor

Overview

Maori's armor is composed of three HDPE components. This consists of two side armor blocks and a plate mounted to the back.

Design Decisions

test

- Notes/Helpful Advice

- test

Drive

Overview

test

Design Decisions

test

Calculations

test

- Notes/Helpful Advice

- test

Weapon

Overview

Maori's weapon system consists of a steel drum to cause damage to opponents and two aluminum hubs to interface the weapon with the chassis. The drum is constrained to the hubs with bolts perpendicular to the axis of rotation to minimize loosening caused by vibration. The fork shape of the hubs compromises ease of machining with functionality.

Design Decisions

Beater Bar

- Material: S7 Tool Steel

- Profile: prioritized compatibility for EDM

- constant cross-section

- axisymmetric to avoid vibration induced by skewed center of mass

Hubs

- Material: Aluminum 6061-T6

- machined in house, so ease of machining outweighed material selection

- the brunt of forces are received by the beater bar and chassis, this material selection allows

deformation of hubs before the beater bar and chassis, which took longer to machine

- Shape:

Calculations

test

- Notes/Helpful Advice

- test

Electronics

Overview

Drive

test

Weapon

test

- Notes/Helpful Advice

- test