Difference between revisions of "How to Guide Inventor"

(→Making a Part) |

(→Normal) |

||

| Line 43: | Line 43: | ||

====Normal==== | ====Normal==== | ||

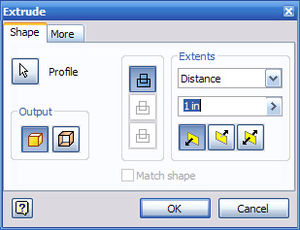

| + | [[Image:Inv_extrude_win.jpg|thumb|right|Normal Extrusion Window in Inventor]] | ||

This makes a perpendicular projection of set length from a selected profile (sketch). To do this hit E. A window will appear with options on how to preform the extrusion. | This makes a perpendicular projection of set length from a selected profile (sketch). To do this hit E. A window will appear with options on how to preform the extrusion. | ||

Revision as of 16:50, 3 September 2007

Inventor, produced by Autodesk, is the 3d solid modeling software currently used in the FIRST Robotics Competition (this guides target) and by our RoboCup Small Size team. The software can be downloaded for free at http://students.autodesk.com (you need a valid email address from a college ie. your @gatech.edu address). The most recent release is Inventor 2008 (which is what this guide will use).

Contents

Setting Up Inventor

In order to do anything you need to setup your project file. By creating this you can more easily keep track of just project X or project Y and have them on the same machine.

To Do This:

- Go to File

- Projects

- Click the new button

- Fill in the requested info

Note: There are many ways to get to the projects window.

Now you will have you new project listed in the project window. However when you start inventor you will not by default be working in it. To make this the default project just double click on your project in the list. Now when you start you will always be working with it.

Making a Part

First we need to create a part file. To do this File > New > Select Standard.ipt

Making a Sketch

Like AutoCAD (also made by Autodesk) Inventor has many shortcut keys (some of them are the same). To your left you will see two panels. On the top you have Model and on the bottom you have 2D Sketch. The bottom panel will change depending on what you are doing (Note: these are the default locations and these windows are movable). You will also notice beside each title there is a drop down arrow these provide more features which you can explore. Though generally you will not use these additional features.

Generally (by default) the top panel will house info about the current file you are in and the bottom panel will hold commands that you can use to create your product.

Lines

To do a line you can hit L and then click around to draw what you need to. To stop drawing lines (along with any other command) hit Esc.

Circles

There is more than one way to make a circle. By default and when you hit C it will make one from the center of the point that you select. To change this click the down arrow beside the circle button.

More

You can also create boxes. More importantly there is a trim command short cut X. With trim you could draw a triangle and place a circle on the end of it. Then remove only the lines that you want and end up with an ice cream cone.

Project Geometry is is by far one of the most useful tools (later on once you have more than one file). With this you can bring forward outlines from other parts or features on the same part and create sketches that a driven off of something else. These sketches will automatically update when that something else is changed.

Dimensioning

Before we go any further we need to fully dimension our sketch. This keeps it from changing and locks it in place. As of now all of our lines will be green and once we are done they will be black. To get started hit D. (Note: You can auto dimension the sketch however sometimes it is better to manually do it. You may want your sketch to be based off of direction X or Y and keep this or that side more readily adjustable.) You may need to specify its distance from the origin. To do this make the axises visible and project their geometry.

Once you have created a dimension you can edit it by click on it (it will go from black to red while hovering). You can input any formula you want.

A dimension can also be based of off of other dimensions. To do this simply create a dimension like you would normally and edit it. Once the window is up for you to key in a formula or number click on the dimension(s) you want it to be based off of. You can then manipulate them as if they were variables in an equation (which they are).

Extrusions

In order to make your 2-dimensional sketch into something more tangible you will need to utilize various extrusions depending on your situation. Overtime you will figure out what your situation is and what to do.

Normal

This makes a perpendicular projection of set length from a selected profile (sketch). To do this hit E. A window will appear with options on how to preform the extrusion.

To preform a Normal Extrusion:

- Hit E

- Select profile or sketch

- Key in distance

- Select direction (Forward, Backward, or 1/2 forward & 1/2 backward)

Revolved

Produces a rotation of X degrees around a specified axis. You can added a line to your sketch and use it as that rotation axis or use an edge of the sketch.

To preform an Revolved Extrusion:

- Hit R

- Select the profile or sketch

- Select axis of rotation

- Specify extent (Full = 360, To = To a face, To From = From one location to another location, Angel = Specify degree)

Swept

Holes

It is better to you the hole tool when placing holes instead of drawing the into you sketch initially. This will allow you to edit them with out going back in to the sketch later and there for save you some time. It will also allow to specify the thread, the depth, if its counter sunk and so on.

Properties

Now that you part is complete you are not done! Go to File > iProperties > Physical Tab

Set your material type and hit update. Then apply and close the window. Doing this allows inventor to a) give you and estimated weight of your robot and b) give you a estimated cg location. Note: If you have a part like fan or an entire assembly like a motor you can weight the thing and thne manually key in its mass on that window.

Putting the Parts Together

Now that you have your parts lets put them together to make some sort of subsystem, product, etc. To do this you will need to create an assembly. Note: Assemblies can be composed of parts and other assemblies.

Ideally your robot's assembly structure could look like this:

- Main Robot Assem

- Drive Train Assem

- Gearbox Assem

- Gears (Parts)

- Plates (Parts)

- Shaft (Parts)

- Gearbox Assem

- Frame Assem

- Tubes / Angle (parts)

- Bolts (parts)

- Manipulators

- Bumpers

- Drive Train Assem

Constraints

Making what you just did Useful

Drawing Files

Dimensioning

Appendix

Useful Short Cut Keys

- Inventor Wide

- Zoom to fit = Home

- Look at face = Page Up

- Ending a command = Esc

- Parts

- 2D Sketches

- line = L

- circle = C

- trim = X

- dimension = D

- Modeling

- Extrude = E

- Revolve = R

- Fillet = F

- Mirror = Ctrl + Shift + M

- Circular Pattern = Ctrl + Shift + C

- Rectangular Pattern = Ctrl + Shift + R

- Loft = Ctrl + Shift + L

- Sweep = Ctrl + Shift + S

- 2D Sketches

- Assemblies

- Drawings