Chonkii

Contents

Introduction

This robot had a name before a design. It born when Brian thought to himself, "Hey, it would be really funny if we named a robot Chonki and made it really, really big and really really loud..." Throughout the design process the robot lived up to its name. Chonkii is a 45lb shuffling shell spinner competing in the 30lb weight class that serves as an iteration on the original Chonki, which was never fully constructed. It was developed during 2021-2022. The drive system was iterated from that of Apachi and Chonki. The weapon system was a brand new concept for BattleBots. The goal of Chonki was to evaluate the viability of shell spinners while taking advantage of the 1.5 times weight multiplier afforded by using a mechanism other than wheels for movement. Competed at Motorama 2022 and finished with a 2-2 record.

Members:

- Mihir Naharaj (Lead)

- Brian Epstein (Mentor)

- Janie Edgar

- Sydney Baker

- Thomas Jackson

- Cole Sosnowski

- Christopher Bellflowers

- Emily Liu

Drive System

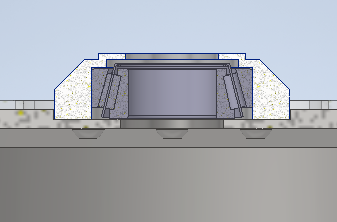

Chonki utilizes a shuffler system for drive. It consists of two shuffler modules, each with 4 HDPE feet. The feet sit on two parallel, octagonal cam shafts. These allowed for the four feet to be positioned 90 degrees from each other, so feet would always be in contact with the ground through the cam shaft's rotation. To fit inside the feet get smaller as they move away from the chassis. The longer feet have chamfers to clear the rollers and support which they sit under. The cams have offset octagonal holes to accommodate the shafts and sit inside circular cutouts in the feet, which keep them parallel with the ground as it walks. The use of the shuffling system allowed Chonki a weight bonus, bringing the max weight to 45 lbs.

Weapon System

Design Considerations

Since the weapon on this bot also serves as its armor, it was imperative that the weapon be large enough for the robot to fit inside. An additional constraint was that it must be small enough that a reasonable thickness could be attained while still remaining under the desired percentage of the total weight of the robot (~50%).

Nested Concept

Originally the shell was designed as a series of rings with progressively increasing diameters. The method of joining these rings together was thoroughly discussed. The two primary options were use of fasteners and through welding. This concept was advantageous because it allowed for the rings to be cut from sheets using the waterjet

Fastener Method

Advantages:

- Avoids need to use welding (process with which we had little experience)

- Simple to align via hole placement in ring

Easy to replace damaged bolts and or rings Disadvantages:

- Bolts are likely to shear under stress from hitting other bots

- Addition of holes to rings add stress concentrator, increasing likelihood of failure

Welding Method

Advantages:

- Very strong joint between rings if done correctly

- Difficult to align rings and keep them aligned (flats were included on rings for this purpose, but a jig would still be required)

Disadvantages:

- A single piece means the whole thing must be replaced after damage

- Welding is hard lol

Solid Concept

Instead of doing the nested concept, we simply decided to kill the Earth and mill the shell out of a massive block of steel. With all the garnet required for the waterjet design, wasting 90% of a 200 steel block was still cheaper.

Pros:

- Less expensive than the nested ring design

- Made from one solid piece so it didn't have connection points to fail at

- Lives up the it's name

Cons:

- 200 lbs of steel is heavy and our plan was to "just like, pick it up I guess" (admin got mad)

- Shell exceeded the y axis on the HAAS which complicated the CAM

- The block is still sitting in the shop and it's getting lonely

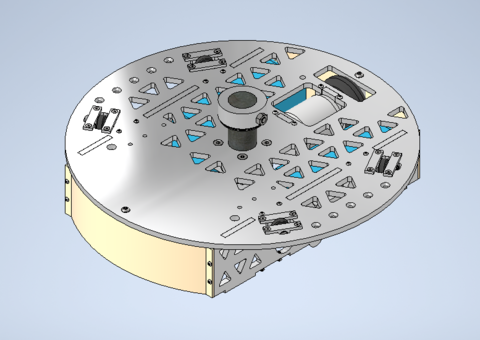

Weapon Shaft Interface

A tapered roller bearing fits into a housing that is attached to the top of the shell.

Belt-Driven vs Wheel-Driven

- Two primary methods were considered for driving the weapon: a belt/sprocket and chain system or a wheel-based system.

- The belt was dismissed due to the various past issues, such as poor tensioning, temperature deviations, and general slipping.

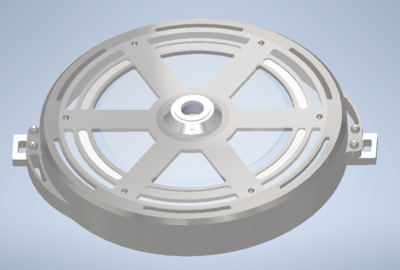

- Inspired by Hyperpolarized, it was later decided to drive the weapon by using a single driven wheel at the top of the bot, with rollers along the surface to give additional support. A central shaft was used as a dead axle support.

Editing Chonki Design Guide (section)

Jump to navigationJump to search

Chassis System

- The chassis mostly consisted of aluminum, featuring of a ¼” top and side plates and ⅛” bottom plate.

- The front and back plates were made of HDPE, which bent to form Chonki’s robustly round shape.

- The chassis had multiple rollers spaced out along its top, giving additional support to the shell track above.

- The central dead axle was constrained by two blocks, mounted to both the top and bottom plates. However, it was later determined that aligning the shaft along the two blocks was incredibly difficult, and a single longer block would have proven to be a superior solution.

- While drilling through the blocks into the shaft, a drill bit melted inside, acting surprisingly well as a pin.

Electronics

| Drive Motors | Turnigy Aerodrive SK3 - 5055-280KV Brushless Outrunner Motor

|

| Drive Motor Controllers | Flipsky Dual FSESC6.6 Based upon VESC6 with Aluminum Heatsink Mini Size |

| Weapon Motor | Scorpion SII-4035-250KV |

| Weapon Motor Controllers | AeroStar Advance 120A HV (6~12S) Brushless ESC (Opto) |

| Receiver | Hobby King 2.4Ghz Receiver 6Ch V2 |

| Remote Control | Hobby King 2.4Ghz 6Ch Tx and Rx V2 |

| Battery | 2x Turnigy Heavy Duty 5000mAh 6S 60C LiPo Pack w/XT90

2x Turnigy Graphene Panther 3000mAh 3S 75C Battery Pack w/XT90 |

Trivia

- The Vectrax was rendered inoperable twice by Chonki members (mainly Brian) during its construction.