Mandiv Design Guide

Contents

Introduction

Welcome to the Mandiv Design Guide! Mandiv is the fourth iteration of a 120 pound drum spinner created by RoboJackets. The purpose of this guide is to explain all of the reasoning behind the design decisions during the creation of Mandiv. This guide will go in depth on why certain designs were chosen as well as explaining some of the calculations used to support those decisions.

Design Basics

Chassis

Overview

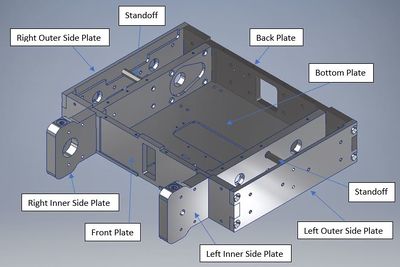

The chassis of Mandiv consists of eight parts: the left and right inner side plates, left and right outer side plates, front plate, back plate, top plate, and bottom plate. These eight plates are the frame of the robot and are what hold the entire robot together.

Design Decisions

We designed the different pieces of the chassis to puzzle fit together. This was because puzzle fitting allows for stronger connections between plates as well as providing easier assembly due to each plate being able to fit in place without screws being needed to hold it there. Screws were then used to attach each plate to one another, ensuring the whole chassis remains intact.

Each plate was pocketed in certain areas in order to reduce the overall weight of the chassis, to allow for some other parts to be inset in the chassis, and to provide some extra clearance between the chassis and other parts of the robot.

Differences from Mandiii

The main differences between Mandiv's chassis and Mandiii's chassis are the overall length and width of the robot, the thicknesses of the front and back plates, a standoff is used to support the middle of the outer side plate instead of an aluminum plate, and the pocketing of the outer side plates.

The overall length and width of Mandiv was designed to be shorter than that of Mandiii in order to reduce the overall profile of the robot.

The thicknesses of the front and back plates were increased so that a larger screw could be used to attach the outer side plates.

We decided to use a standoff instead of an aluminum plate because the plate effectively acted like a standoff and using a standoff reduced overall machining time.

The pocketing on the outer side plates was changed due reduce the risk of those plates bending, which was a problem at competition for Mandiii.

Notes/Helpful Advice

The water jet's tolerancing isn't perfect, so when designing puzzle fits, add a tolerance of around 0.007 inches to both sides in order to ensure that the pieces fit together easily. This will save a good amount of time because you won't need to file the pieces to make them fit together.

When starting your CAD, link an excel file to your parts and use the excel file to create parameters that you use as dimensions. This will allow you to go change the parameter value in excel, which will then update all CAD parts that use that parameter. This will save you from having to go in and change that value on every CAD part when you just simply want to change the overall length of your robot. Instead, you just have to change the one number in excel and everything will update for you. This will save you a lot fo time when playing around will the sizing of your different parts in the future.

Drum Assembly

Overview

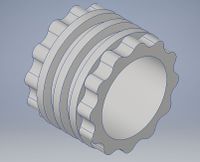

The drum is Mandiv's only weapon and is what's used to cause damage to opposing robots. Mandiv's drum assembly is made up of two separate drum halves, which are connected with a pulley in the middle. The drum halves are constrained to the pulley via a spline and a force pushing the drums on the spline cause by tightening screws from the inner side plates into the drum shaft.

Design Decisions

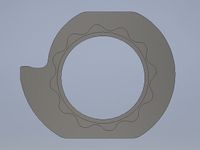

We decided to make the overall shape of the drum using a spline instead of just a typical circle with a tooth coming out of it. This decision was made because it significantly increased the moment of inertia for the drum. It also allowed for us to have a bigger tooth (more reach) than if we had just a circle with a tooth.

We decided to put the pulley between the two drum halves instead of on one of the sides in order to protect it a little more. This is because when the pulley is on the side, it is more exposed to taking hits from other robots (especially horizontal bar spinners). The thought process of moving it to between the drums is that it would no longer be exposed to hits from the sides, and that other robots would hit our drum before hitting the pulley.

A spline was used to attach the drums to the pulley because it was calculated that the spline provides the strongest shear strength and safety margin of the methods we tested. The diameter of the weapon shaft was increased in order to reduce the chance of bending (hopefully eliminate the chance of it).

The flats were added onto the drum to provide an area to clamp the drum in order to make machining it easier.

Calculations

The shaft bending calculator takes in the dimensions as well as the amount of bending that occurred on that shaft in order to calculate the necessary force required to bend that shaft by that amount. It then calculates the safety margin for the shaft for if that force were to be occurred (no surprise it was negative since that shaft was bent). We then used this data to determine the shaft diameter necessary to withstand that type of force (positive safety margin) in order to determine what diameter we wanted to make our shaft this year.

The drum stress sheet is what we used to calculate the shear strength of the spline attaching our drums to the pulley. This is done by inputting a force that you want to test and then inputting the dimensions of the spline in order to test the margin of safety for when that force is applied. We then repeated this process for the dowel pins that Mandiii used in order to determine that the spline has a significantly stronger shear strength than the dowel pins used last year.

This sheet also tested to see if the bearing seats for the thrust bearings on the drum were big enough to withstand the forces that would be on the bearing.

The spinup sheet takes in the weapon motor specs, the pulley diameters, the power, and the drum's moment of inertia in order to calculate the spinup time for the drum.

Note

All drum calculations can be found in the Mandiiii Dropbox under the design calculations excel file (drum stress and spinup sheets) and the shaft bending calculator excel sheet (weapon shaft bending calculator).

Differences from Mandiii

The main differences between Mandiv's and Mandiii's drum assemblies are: the shape of the drum, the use of a spline to connect the drums instead of dowel pins, the location of the weapon pulley was moved to between the drums instead of on one side, and the diameter of the weapon shaft was increased to prevent bending.

Gearbox

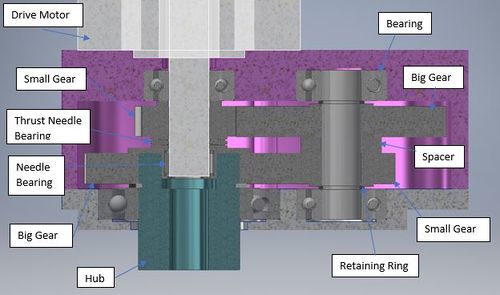

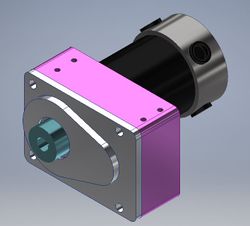

Overview

This gearbox is used with our drive motors in order to change the speed Mandiv is going vs if just the motor itself was used. This gearbox utilizes a reverse compound gear train and a hub to make the output and input shafts completely in line. The gears and hub are all constrained laterally by spacers and retaining rings. The drive motor is attached to the base of the gearbox (in pink) and the gearbox itself is attached to the top and bottom plates with screws.

Design Decisions

We decided to use a reverse compound gear train in order to make the overall size of the gearbox shorter.

One of the biggest obstacles with designing a reverse compound gear train is dealing with the input and output shafts. This is because they are in live with each other, but spinning at different speeds. We decided to address this issue by making a hub for inside of the gearbox that would allow for a smooth transition from the input shaft to the output shaft without having to put a wall in between the two shafts. This decision was made instead of just simply adding a wall to separate the two shafts because adding a wall would mean the gearbox would have to get bigger than if we just made the hub. However, the hub will be harder to machine, so it's a trade-off.

We wanted to increase the overall drive speed of Mandiv, so we decided to use some bigger gears and up the gear ratio in order to make the robot faster than in previous years.

Calculations

The drive calcs sheet uses the drive motor specs (RPM), the robot weight, the wheel diameter, and the number of teeth on each gear in order to calculate the gear ratio and the output RPM from the gearbox. It then uses these values to calculate the max speed that the robot can drive at as well as its maximum pushing force. (Note: Remember there's a trade-off between torque and speed).

The gear stress calculator uses the gear specifications, the forces on each gear, and your desired safety margin in order to calculate the maximum stress on each gear that fits those specifications.

Differences from Mandiii

The gearbox Mandiii used was just a compound gear train whereas the one Mandiv is using is a reverse compound gear train. This decision was made because we wanted to decrease the overall footprint of the gearbox within the robot.

The gear sizes were changed in order to get a different gear ratio that would allow us to drive faster than Mandiii could (after comp with Mandiii, we felt that Mandiii was slower than other robots, so we wanted to make Mandiv be able to drive faster).

Notes/Helpful Reminders

The gears are constrained to the shafts via a key. This is crucial because without it the shaft and gear would spin independently.

The gearbox base (pink) and lid (grey) are made using the Haas and attached via the four screw holes shown on the lid.

All calculations for the gearbox can be found in the Mandiiii Dropbox in the design calculations excel file (drive calcs sheet) and the gear stress calculator excel sheet.

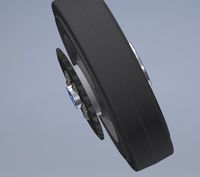

Drive Assembly

Overview

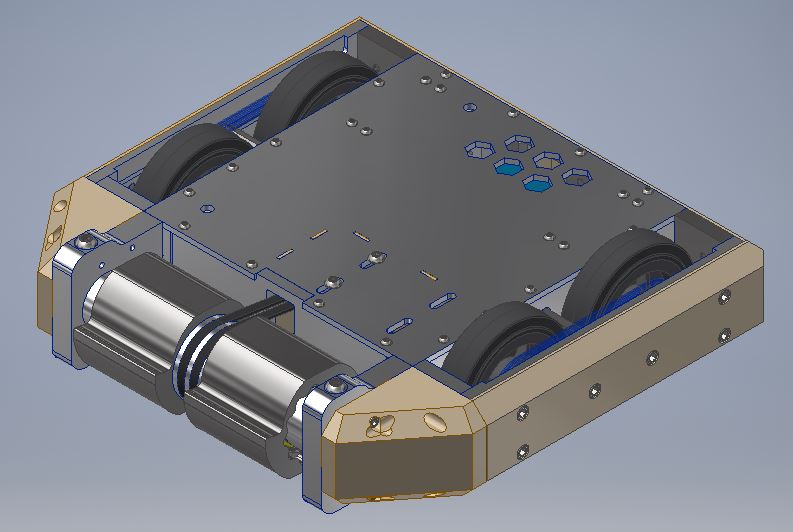

The drive assembly consists of four wheel drive with the back wheels on each side being powered by the gearboxes and the front wheels being powered by a chain that is connected to the back wheels. The shaft on the back wheels come out from the gearbox hub (aka the output shaft of the gearbox) and is constrained with retaining rings. Each wheel has a hub that constrains the wheel to the shaft via a key. In addition, the hub is connected to a sprocket which is what powers the chain. There are also spacers on each side of the wheel in order to help constrain it laterally.

Design Decisions

The wheel hub and the wheel spacers were designed to be as simple to machine as possible to help counteract the extra time the gearbox hub will take to make.

The spacing between wheels was determined by using chain lengths. This is extremely important because if you don't design with chain length in mind, there is a high chance that you won't get a proper fitting chain for the length you designed.

Differences from Mandiii

We decided to make the hub in each wheel slightly bigger than Mandiii's in order to use bigger screws and button heads instead of countersunk screws.

We changed the design of the spacers on each side of the wheel in order to make them simpler to machine.

Notes/Helpful Advice

Use the chain tool in Inventor to make your chain. This will help you get an accurate distance needed between wheels (can't have half links, only full links) as well as providing an accurate weight for your chains in the CAD.

Armor

Overview

The armor for Mandiv is made up of 7/8 inch HDPE (high-density polyethylene). There are six pieces: the left and right corner blocks, left and right sides, and the left and right back pieces. The armor is attached with socket head screws that screw into the chassis.

Design Decisions

Each piece of armor has a chamfer on the top and bottom to try to make more impacts just glancing blows instead of full on hits. The chamfers don't extend all the way to the corner of the part in order to make it a little easier to clamp the parts when machining.

The armor is only 7/8 inch thick because we looked at Mandiii's plastic armor from competition and the deepest impact was only half an inch.

Differences from Mandiii

Mandiii's armor had aluminum plating as well as the plastic armor. We decided to forego the aluminum plating because at competition it looked like the aluminum provided little in the way of protection and easily got torn off (which it was designed to do, but to the judges it looked like the armor was getting torn up).

Mandiii also used thicker plastic than we're using, but since the deepest gash was only about half an inch, we think 7/8ths should be enough.