Difference between revisions of "Materials Database"

(→S7 Tool Steel (at 54 HRC)) |

(→S7 Tool Steel (at 54 HRC)) |

||

| Line 107: | Line 107: | ||

*Anecdotal experience from other builders shows it fails through fracture before bending | *Anecdotal experience from other builders shows it fails through fracture before bending | ||

*Considered to be less tough than AR500 and is commonly used when the higher hardness (C54 vs C48) is desired like for weapon teeth | *Considered to be less tough than AR500 and is commonly used when the higher hardness (C54 vs C48) is desired like for weapon teeth | ||

| − | *Extra important to avoid sharp corners and stress concentrations to prevent cracks from forming | + | *Extra important to avoid sharp internal corners and stress concentrations to prevent cracks from forming |

===AISI 4340 Steel=== | ===AISI 4340 Steel=== | ||

Revision as of 04:32, 17 December 2022

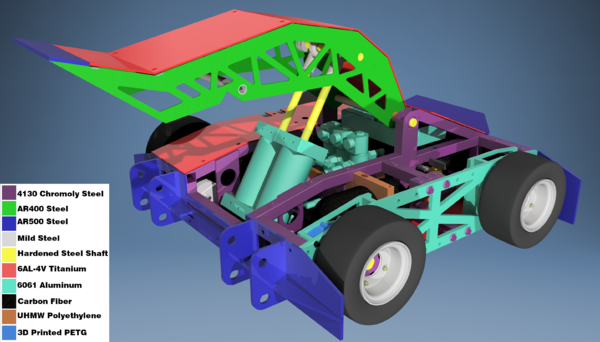

This is a brief database of useful properties for commonly used materials within battlebots as well as some background information and peoples' experience working with them. Some material properties have not been included but feel free to add anything important. Material properties usually vary slightly for a given material from vendor to vendor so in the majority of cases, trust specs given by the manufacturer or supplier over the specs in this database when they are given. In addition, some of these material properties can vary slightly depending on the data source and also other details such as heat treatment and the kind of sample the material data was acquired from.

- Note: Utilizing fracture toughness and toughness calculated using fracture toughness is somewhat suspect in terms of accurately representing impact toughness for some materials but is the only consistently found property.

- RoboJackets in the future should perform charpy/izod impact tests on standardized samples of each material to more accurately compare impact strength properties for our applications

Contents

Steels

AR500 Steel

| Type | Carbon Steel |

| Modulus of Elasticity | 30,000 ksi |

| Poisson's Ratio | 0.29 |

| Density | 0.29 lb/in^3 |

| Ultimate Tensile Strength | 225 ksi |

| Tensile Yield Strength | 200 ksi |

| Brinell Hardness | 450 HB |

| Rockwell Hardness | C48 |

| Elongation at Break | 12% |

| Familiar Sellers | McMaster Carr, MakeItRingTargets, Alro Steel, SendCutSend |

Material Description:

- High strength, high hardness, abrasion resistant steel used in body armor and shooting targets

- Generally considered to be tougher than S7 tool steel but has lower hardness

- Hardened steel is very difficult to machine, is typically only used for Waterjet parts

- No further heat treatment needed

- Typically used for weapons and wedges due to it's high strength, toughness, and relatively high hardness

- Used more commonly as armor in higher weight classes

- Anecdotal experience from builders says that AR500 typically bends before it fractures

- Will rust over time when wet or exposed to air

AR400 Steel

S7 Tool Steel (at 54 HRC)

| Type | Carbon Steel |

| Modulus of Elasticity | 30,000 ksi |

| Shear Modulus | 11900 ksi |

| Poisson's Ratio | 0.29 |

| Density | 0.282 lb/in^3 |

| Ultimate Tensile Strength | 284.9 ksi |

| Tensile Yield Strength | 220.4 ksi |

| Fracture Toughness (Riobotz Sample) | 50.0 ksi-in½ |

| Calculated Toughness | 9.42 J/in^2 |

| Brinell Hardness | 543 HB |

| Rockwell Hardness | C54 |

| Elongation at Break | 6.5% |

| Familiar Sellers | McMaster Carr, OnlineMetals |

- Shock resisting tool steel that has high strength and high impact toughness

- Usually used in weapons but has been used by some NHRL builders for shafts but with hardnesses much lower than 54 HRC

- Is machined in its annealed form and then heat treated, quenched, and tempered to exactly 54 HRC which is a value recommended by the Riobotz Combot Tutorial pg 59-60.

- Ray Billings, builder of Tombstone, also endorses exactly 54 HRC for S7

- Anecdotal experience from other builders shows it fails through fracture before bending

- Considered to be less tough than AR500 and is commonly used when the higher hardness (C54 vs C48) is desired like for weapon teeth

- Extra important to avoid sharp internal corners and stress concentrations to prevent cracks from forming

AISI 4340 Steel

AISI 4140 Steel

Aluminum Alloys

Aluminum 6061-T6

| Type | Aluminum Alloy |

| Modulus of Elasticity | 10,000 ksi |

| Shear Modulus | 3800 ksi |

| Poisson's Ratio | 0.33 |

| Density | 0.0984 lb/in^3 |

| Ultimate Tensile Strength | 45 ksi |

| Tensile Yield Strength | 39 ksi |

| Fracture Toughness (T-L dir) | 26.4 ksi-in½ |

| Calculated Toughness | 7.88 J/in^2 |

| Brinell Hardness | 93 HB |

| Rockwell Hardness | B52 |

| Elongation at Break | 10% |

| Machinability (Vs. 1112 Steel) | 270% |

| Familiar Sellers | McMaster Carr, Midwest Steel Supply, SendCutSend |

Material Description:

- Lightweight aluminum alloy that comes already pre-heat-treated T6 temper which gives it its strength

- Beware of tempers T4 and O which are weaker than 6061-T6

- Typically used for frame rails, plates, pulleys, and armor for some bots

- Tends to fail in bending before fracturing

- Tends to "ablate" and may take gashes when hit directly by weapons

- Easy to machine and relatively cheap

Aluminum 7075-T6

| Type | Aluminum Alloy |

| Modulus of Elasticity | 10,000 ksi |

| Shear Modulus | 3800 ksi |

| Poisson's Ratio | 0.32 |

| Density | 0.102 lb/in^3 |

| Ultimate Tensile Strength | 81 ksi |

| Tensile Yield Strength | 69 ksi |

| Fracture Toughness (T-L dir) | 22.8 ksi-in½ |

| Calculated Toughness | 5.87 J/in^2 |

| Brinell Hardness | 150 HB |

| Rockwell Hardness | B87 |

| Elongation at Break | 7.9% |

| Machinability (Vs. 1112 Steel) | 170% |

| Familiar Sellers | McMaster Carr, Midwest Steel Supply, SendCutSend |

Material Description:

- Aerospace grade aluminum alloy which is much stronger and harder than 6061-T6

- Pre-heat-treated to T6 temper

- Past and anecdotal experience notes that it tends to fracture before it bends as it's more brittle than 6061

- Some builders recommend avoiding using it as armor or for parts that take direct hits due to fracture risk

- Relatively easy to machine and is more expensive than 6061-T6

Aluminum 2024-T6

Other Metal Alloys

Grade 5 Titanium (Ti-6Al-4V)

| Type | Titanium Alloy |

| Modulus of Elasticity | 16510 ksi |

| Shear Modulus | 5800 ksi |

| Poisson's Ratio | 0.32 |

| Density | 0.160 lb/in^3 |

| Ultimate Tensile Strength | 138-150 ksi |

| Tensile Yield Strength | 128-140 ksi |

| Fracture Toughness (Annealed Plate) | 67.9 ksi-in½ |

| Calculated Toughness | 31.5 J/in^2 |

| Brinell Hardness | 310 HB |

| Rockwell Hardness | C34 |

| Elongation at Break | 6.7% |

| Machinability (Vs. 1112 Steel) | 20% |

| Familiar Sellers | McMaster Carr, SendCutSend, TMS Titanium |

Material Description:

- Very high strength and high toughness metal alloy

- Denser than aluminum but less dense than steel. May destroy tools if you're not careful

- Typically sold and used in its annealed state for high toughness. No heat treatment needed.

- Typically used for armor, structural plates, sometimes weapons, it's pretty versatile material overall

- Very expensive

- Very difficult to machine or drill due to work hardening properties

- In some cases, outsourcing to SendCutSend might be financial preferable to buying Ti stock so discuss with your PM

Plastics and Polymers

Ultra-High-Molecular-Weight-Polyethylene (UHMW)

High-Density-Polyethylene (HDPE)

Carbon Fiber

Sources

- AR500 Steel: SendCutSend, McMaster Carr, Steel Warehouse

- S7 Tool Steel: Riobotz Combot Tutorial, Ansys Granta Edupack

- Al 6061-T6: SendCutSend, Matweb, Machining Doctor

- Al 7075-T6: SendCutSend, Matweb, Machining Doctor

- Ti-6Al-4V: SendCutSend, Matweb, Machining Doctor