Difference between revisions of "RoboCup: Redesign 2014-2015"

(Transclude Ball Sens information) |

m |

||

| Line 437: | Line 437: | ||

---- | ---- | ||

| − | {{:RC15BallSense | + | {{:RC15BallSense}} |

=== Kicker Board & Detection === | === Kicker Board & Detection === | ||

Revision as of 19:37, 27 January 2015

Contents

- 1 Phase I: Techanical Analysis

- 2 Phase II: Design

- 3 Phase III: Production

Phase I: Techanical Analysis

The first stage of the 2014-2015 RoboCup redesign involves brainstorming potential upgrades by researching new technologies/resources since the last revision. A parallel analysis of current robot bugs and potential enhancements is also done at this time. Outlined below is a listing of resources that the team used in this brainstorming stage.

Competition 2014 documentation

Team Description Papers (TDP)

Phase II: Design

During the design phase, specifications are determined for each section of the robot. Experimental results are documented here from all quantitative findings. This phase is also where the high-level ideas from Phase I are tracked to ensure completion.

Microcontroller/FPGA Processing

To Do

- Successfully communicate over SPI with a current FPGA and mbed

Completed

- Build development board for testing FPGA configuration from mbed's flash storage

- Tested and confirmed working

- Obtain mbeds for robot use

- How: 15 mbeds donated by ECE department

Mechanical/Electrical Integration

To Do

- Determine best solution for integrating serial identification to mechanical bases

- Add connection header for ball sensor to control board

- Test motor wire modifications before working on the entire batch of motors

- Determine kicker connections and integration

- Tentative plans for a PCI Express Mini conenction on the motor board's edge

- Determine options using quarter-turn screws for electrical board attachment

Completed

- Research options for using Altium for schematic and board layout designs

- Completed Task: Contact them for a 30 day trial

- Outcome: Altium sponsorship with 6 "On-Demand" licenses for Altium Designer

- Determine location and placement for dribbler motor header

- Update hall connection header to right angled one

- Add pin locations to all connection housings in CAD part files

Update the 14-pin connection header (female) for the control-to-motor board connection- Update: Abandoned for different board-to-board connectors

- Finalize method for adjusting motor wire lengths when motors arrive

- Decision: Unsolder from motor's PCB, trim to length, and resolder to motor's PCB

- Reason: Did not want to delay ordering motors any futher & hand soldering results in higher yields compared against hand crimping

- Determine placement of battery location

- Decision: Horizontally under all electronics

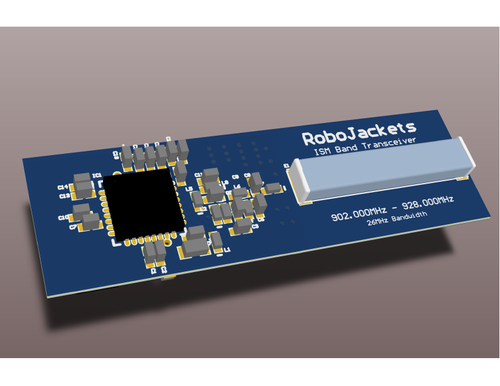

Radio

Current protocol [LINK TO BE CREATED & UPDATED]

To Do

- Obtain breakout boards for CC1201 transceivers with integrated ANT-916-CHP antenna

- Order CC1201 samples from TI

- Current quantity:

21

- Current quantity:

- Successfully communicate using two (2) CC1201 transceivers and two (2) mbeds

- Research and determine best steps for structuring radio protocol with primary and seconday frequencies

- The Crazyflie project has basic radio documentation for how they implemented real-time communication with room for expansion

- Test packet optimizations - Nanopb is promosing for this

Completed

- Obtain TI's CC Debugger for interfacing transceivers with SmartRF Studio

- How: Digi-Key

Successfully communicate using two (2) nRF24L01+ transceivers and two (2) mbeds- Result: Task abandoned. Determined that a 2nd frequency band provided only nominal benefits

- Test methods using breakout boards and compare data rates

- Result: Packet processing (

~60 bytes) for receptions estimated to consume0.2msto0.3msof processing time @60 packets/sec

- Result: Packet processing (

- Determine optimal secondary frequency for base station updates

- Decision: End result's data rate is only nominally benefitial for high-throughput broadcasting. No 2nd transceiver

- Research integration options of the CC1111 and nRF24LU1+

- Decision: Do not use SoC parts for the base station

- Reason: Keep radio software on the mbed platform's C++ libraries (SoC would require additional C code for the base station)

- Order five (5) CC1111 transceivers from TI

- Successfully communicate using two (2) CC1101 transceivers and two (2) mbeds

- Obtain breakout boards for CC1101

- How: Added SMA antenna connector to breakout boards from 2008 fleet

- Obtain breakout boards for nRF24L01+

- How: eBay

FPGA

A few minor changes to the FPGA's Verilog code must be made for the 2015 redesign. This includes migrating the [2C] interface with the kicker board to the mbed platform & enhancing encoder connections to support the new differential signals.

Setting up a computer for Verilog development

- Create an account on Xilinx's website

- The Xilinx program is called ISE Design Suite (this is on ECE's virtual lab pool computers - can connect to it from anywhere).

- The desired download link is found under the ISE Design Suite heading

- The current version at the time of this writing is 14.7 (size: ~6GB)

- The ISE Design Suite is no longer supported

- The newer version of Xilinx's software is called Vivado Design Tools, but it does not support the Spartan-3E FPGA

- Install the program to your computer

- The installer will prompt you to select an edition to install

- Select ISE WebPACK

- The installer will prompt you to select an edition to install

- Obtain a license at the Xilinx page for license management

- Open the link sent to you after requesting a license

- Navigate to the Manage Licenses tab

- Download the license called ISE WebPACK License

- Save the downloaded license file to the

~/.Xilinxdirectory of your computer- The program will require you to locate the license's path at first startup

Mandatory user-provided files for Verilog synthesis

- Verilog files(s)

- Defines the HDL implementation

- File Extension:

.v

- Xilinx Constraint File

- Defines parameters for correct synthesis to the hardware (pin mappings)

- File Extension:

.ucf

FPGA Commands

| Command | Read/Write | Definition |

|---|---|---|

0x00

|

Read Only | Receive Data Readings |

0x01

|

Read/Write | Set motor speeds |

Example SPI Transfer (0x00 Read)

| Array Index | Bit(s) | Definition |

|---|---|---|

0

|

7..0 | FPGA Version (0x04 in 2014)

|

1

|

7..0 | Encoder 1 Count (LSB) |

2

|

7..0 |

Encoder 1 Count (MSB) |

3

|

7..0 |

Encoder 2 Count (LSB) |

4

|

7..0 |

Encoder 2 Count (MSB) |

5

|

7..0 |

Encoder 3 Count (LSB) |

6

|

7..0 |

Encoder 3 Count (MSB) |

7

|

7..0 |

Encoder 4 Count (LSB) |

8

|

7..0 |

Encoder 4 Count (MSB) |

9

|

7..0 |

Motor Fault |

10

|

7..0 |

Kicker Status |

11

|

7..0 |

Kicker Voltage |

12

|

7..0 |

Hall Count 1 |

13

|

7..0 |

Hall Count 2 |

14

|

7..0 |

Hall Count 3 |

15

|

7..0 | Hall Count 4 |

16

|

7..0 |

Hall Count 5 |

Example SPI Transfer (0x01 Write)

| Array Index | Bit(s) | Definition |

|---|---|---|

0

|

7..0 | Packet Type (0x01)

|

1

|

7..0 | Motor 1 Speed (LSB) |

2

|

7..4 |

Reserved (Always |

| 3..2 | Motor 1 Drive Mode | |

| 1..0 | Motor 1 Speed (MSB) | |

3

|

7..0 | Motor 2 Speed (LSB) |

4

|

7..4 | Reserved (Always 0x00) |

| 3..2 | Motor 2 Drive Mode | |

| 1..0 | Motor 2 Speed (MSB) | |

5

|

7..0 | Motor 3 Speed (LSB) |

6

|

7..4 | Reserved (Always 0x00) |

| 3..2 | Motor 3 Drive Mode | |

| 1..0 | Motor 3 Speed (MSB) | |

7

|

7..0 | Motor 4 Speed (LSB) |

8

|

7..4 | Reserved (Always 0x00) |

| 3..2 | Motor 4 Drive Mode | |

| 0..1 | Motor 4 Speed (MSB) | |

9

|

7..0 | Dribbler Motor Speed (LSB) |

10

|

7 | Kicker Charge |

| 6 | Chipper Enable (1=Chip, 0=Kick)

| |

| 5..4 | Reserved (Always 0) | |

| 3..2 | Dribbler Motor Drive Mode | |

| 1..0 | Dribbler Motor Speed (MSB) | |

11

|

7..0 | Kicker Power (<, 0xFF=6ms)

|

Required Pins

MOSIMISOSCKnCSPROG_B

To Do

- Research the options for interfacing a 7-segment LED into the FPGA for battery voltage & error code displays

- Transition the [2C] bus lines to the microcontroller

- Update Verilog for new differential encoder signals (A+, A-, B+, B-)

- ( (A+) + (A-) == 0 ) should be true for no errors

- Update Verilog for driving a bootstrap circuit

- Add a writable register for enabling/disabling motor encoders

Completed

- Obtain Spartan-3E development board

- How: Found a used board on eBay

- Determine required pins for connecting FPGA

- Documented above

- Document steps for synthesizing Verilog files

- Documented above

- Successfully configured an FPGA from the mbed's on board flash storage

- Successfully synthesized a

Hello WorldVerilog file using Xilinx's ISE Webtools - Determine what communications occur over the SPI bus

- Documented in the tables above

- Finalized that the 2015 motors will use the current FPGA

- Decision: Xilinx Spartan-3E

- Reason: FPGA is only used for motor control & no futher capabilities are needed

Motors

Maxon 50W Custom Motor Drawing

To Do

- Successfully control one of the new 50W motors with an mbed and Spartan-3E interface

- Modify four (4) of the sample motors to accomidate integration into a prototyped robot

- Last Task: Place connectors onto the wires for all four (4) motors

- Order motor controller boards

- Update: Underway

- Test different circuits and document data result set to wiki

Completed

- Order 3 DRV8301 Pre-Drivers from TI

- Update: Many samples from TI are in the electrical room now

- Finalize the protyping designs of single motor controllers

- Order motors

Motion Sensing & Motion Control

GitHub Issue for motion controlling unit

To Do

- Determine best integration options for using motion processor sensor readings for enhancing on-board motion control

- Successfully read sensor data from one of the potential motion processing chips

- Determine if the MPU-6050 is should replace the MPU-9250 according to the benefits of having a 3-axis magnometer

- Integrate the MPU-9250 into the [2C] data bus lines from the mbed

Completed

Error Detection & Indication

To Do

- Determine best solution for controlling the WS2812B RGB LED

- Update: This may be abandoned because of the LED's precise timing for control

Completed

- Determine error LED interface locations with the I/O expander

- Decision: Motor 1, Motor 2, Motor 3, Motor 4, Dribbler Motor, Power Section, Radio Section, IMU Section [Required LEDs: 8

]

Order a Bus Pirate- How: Sparkfun

- Order breakout board for RGB LED

- How: Sparkfun

- Create breakout board for MCP23017 and place on GitHub repository

Ball Sense

Kicker Board & Detection

To Do

- Create a small microcontroller interface for the kicker board

- Original Plan: Use a MSP430G2x from TI

- Updated Plan: Use one of Atmel's ATtiny microcontrollers

- Why: Much easier to implement a custom ISP with the mbed

- Can use the Arduino IDE

- mbed library already exists

- Why: Much easier to implement a custom ISP with the mbed

- Why: To allow for more disjoint kicker board development in future years. An attempt to perform more consistent soldnoid discharges with the microcontroller will be attempted this year.

- Generate snapshots of the 2011 kicker board graphs for reference

- Exported oscilliscope data saved in the firmware directory on software's GitHub repository. Python scripts exist for analyzing the data.

- Use a Serial Identification Chip for unique detection of mechanical bases

- Measure the current from kicker board currently used

- Data exists for the 2011 kicker board. There is a 2011 kicker board (barebone) equipped with a silicon-controlled rectifier and shunt resistor for capturing oscilliscope data for this. Use a digital oscilliscope and export sampled data for waveform recreation/analysis.

- Update the kicker board to accommodate the new battery's voltage of 18.5V

Completed

- Determine the number of capacitors that will be used

- Decision: four (

4)820uFcapacitors

- Decision: four (

Battery & Power

The following contains a listing of batteries that were considered for the 2015 design along with other battery/power adapters and accessories.

To Do

- Determine power switch placement and integration

- Option 1: Use a small switch paired with a relay

- Option 2: Use standard mechanical switch

- Research switching regular modules

- OKI-78SR module

Completed

- Change the first switching regulator to accomidate for the higher voltage battery

- New part number: LM25010

- Finalized the new design's battery selection

- Result: Zippy Flightmax 2200mAh 5S 40C

Battery Accessories

- Connector: XT60 (Male)

- Connector Lead: XT60 12AWG 10cm

- Charging Cable: XT60 Banana Plug

- Balancing Board: Charge/Balance Board

All Batteries

The following list contains batteries that were considered and known about during the battery selction period. The list is not inclusive.

- Zippy Flightmax 2500mAh 5S 20C

- Zippy Flightmax 1800mAh 5S 40C

- Zippy Compact 2450mAh 5S 35C

- Turnig 2200mAh 5S 30C

- Thunder Power 2000mAh 5S 16C

Phase III: Production

The final phase for creating the new fleet of robots involves outlining the steps and procedures for robot manufacturing and assebly. Future members can use this area as a reference for the fleet's required maintenance. It may also be benefitial for strengthening tolerances in future fleet builds.

Electronics Assembly

General

- Sparkfun's PCB assembly process

- EEVblog on anti-static bags for component storage

Solder Paste Stencil Creation

SparkFun uses SolderMask, Inc for their stencil needs

- Laser cutting kapton film

- Material: Kapton Polyimide Film

- Size:

12" x 12" - Thickness:

0.005"

- Size:

- Test Equiptment

- Laser Cutter: Trotec Speedy 300 (

140W)

- Laser Cutter: Trotec Speedy 300 (

- Test Results

- Will not produce required results for making a stencil

- Material: Kapton Polyimide Film

- Chemical etching aluminum

- Untested but very promosing

Prototype PCB Etching

To Do

- Etch CC1201 radio module boards once design is complete

Completed

- Order UV curing lamp

- How: eBay

- Order UV soldermask paints

- How: eBay

- Obtain necessary etching chemicals

- Decision: Hydrogen Peroxide & Muriatic Acid

- Decision: Motor 1, Motor 2, Motor 3, Motor 4, Dribbler Motor, Power Section, Radio Section, IMU Section [Required LEDs: 8