Difference between revisions of "RC08-Dribbler"

Jump to navigation

Jump to search

| (36 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

This page contains the information and documentation of the 2008 dribbler system | This page contains the information and documentation of the 2008 dribbler system | ||

| − | + | ==Assembly Structure== | |

| + | {| border="1" cellpadding="2" | ||

| + | !width="225"|PART NAME | ||

| + | !width="100"|PART NUMBER | ||

| + | !width="50"|QUANTITY | ||

| + | |- | ||

| + | |Mounting Block || RC-2008-04-01 || 2 | ||

| + | |- | ||

| + | |- | ||

| + | |Swing|| RC-2008-04-02 || 2 | ||

| + | |- | ||

| + | |- | ||

| + | |Motor Plate || RC-2008-04-03 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Standoff || RC-2008-04-04 || 2 | ||

| + | |- | ||

| + | |- | ||

| + | |Hinge Shaft || RC-2008-04-05 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |8-32 Lock Nut || RC-2008-04-06 || 4 | ||

| + | |- | ||

| + | |- | ||

| + | |2" Hex Standoff|| RC-2008-04-07 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Dribbler Motor || RC-2008-04-08 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |M2x5 Screw || RC-2008-04-09 || 2 | ||

| + | |- | ||

| + | |- | ||

| + | |Dribbler Motor Gear || RC-2008-04-10 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |6-32 x 3/4 Screw || RC-2008-04-11 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Cross Plate || RC-2008-04-12 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |4mm Snap Bearing|| RC-2008-04-13 || 2 | ||

| + | |- | ||

| + | |- | ||

| + | |Dribbler Shaft || RC-2008-04-14 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Dribbler Roller || RC-2008-04-15 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Dribbler Roller Gear || RC-2008-04-16 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Left Torsion Spring || RC-2008-04-17 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Right Torsion Spring || RC-2008-04-18 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |6-32 x 1/4 Screw || RC-2008-04-19 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |3/8" Washer || RC-2008-04-20 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |Neoprene Rubber Tube || RC-2008-04-21 || 1 | ||

| + | |- | ||

| + | |- | ||

| + | |4-40 Set Screw|| RC-2008-04-22||1 | ||

| + | |- | ||

| + | |} | ||

| − | ==Motor== | + | |

| − | * | + | ==Parts & Components== |

| − | * | + | ===Motor=== |

| + | Fleet motor from Maxon | ||

| + | *Part no: 266521 with attached gear head 118184. | ||

| + | *5.4 gear reduction | ||

| + | *cost: $146.20 each | ||

| + | *[http://test.maxonmotor.com/docsx/Download/catalog_2007/Pdf/07_154_e.pdf Motor Data Sheet] | ||

| + | *[http://test.maxonmotor.com/docsx/Download/catalog_2007/Pdf/07_215_e.pdf Gearhead Data Sheet] | ||

| + | |||

| + | |||

| + | Vendor: MicroMo | ||

* Motor: 12V DC brushless servo motor #E-1628B | * Motor: 12V DC brushless servo motor #E-1628B | ||

**$147.10 each | **$147.10 each | ||

* Planetary gearhead: #E-167 gear reduction: 14 | * Planetary gearhead: #E-167 gear reduction: 14 | ||

* Complete assembly 1628-V-0003 | * Complete assembly 1628-V-0003 | ||

| − | + | Cost: $200.40 each | |

* [http://www.micromo.com/ MicroMo] | * [http://www.micromo.com/ MicroMo] | ||

| Line 16: | Line 96: | ||

* [http://www.micromo.com/uploadpk/e_167_MIN.pdf Gearhead Data Sheet] | * [http://www.micromo.com/uploadpk/e_167_MIN.pdf Gearhead Data Sheet] | ||

| − | + | * Electrical specification | |

| − | * | ||

** 12 Volts | ** 12 Volts | ||

** must have position or speed encoders | ** must have position or speed encoders | ||

** brushless DC | ** brushless DC | ||

| − | == | + | *Maxon motor, the same CMU uses, was chosen for the fleet. This was based on 4wk shorter lead time, $60 cheaper per motor, and significantly greater performance as can be seen from the figures generated by a Matlab script |

| − | + | [[image:motor_comparison.jpg|800 px|Dribbler motor comparison]] | |

| − | + | ||

| − | + | ===Gears=== | |

| − | *roller gear | + | =====Motor gear===== |

| − | **$9.12 each, | + | :Vendor: SDP/SI |

| − | ** | + | :Part No.: A 1B 2MYK05035 |

| + | :Description: Module 0.5, 35 Teeth, 20° Pressure Angle, Brass Gear with set screw, 3mm bore, 17.5mm PD | ||

| + | :Cost: $7.47 | ||

| + | :Drawing:[https://sdp-si.com/eStore/..%5Css%5CPDF%5CSSUM7025.PDF Motor Gear Spec Sheet] | ||

| + | *Connects directly to output of motor and powers dribbler roller | ||

| + | |||

| + | =====Roller gear===== | ||

| + | :Vendor: SDP/SI | ||

| + | :Part No.: A 1B 2MYK05025 | ||

| + | :Description: Module 0.5, 25 Teeth, 20° Pressure Angle, Brass Gear with set screw, 3mm bore, 12.5mm PD | ||

| + | :Cost: $6.03 | ||

| + | :Drawing:[https://sdp-si.com/eStore/..%5Css%5CPDF%5CSSUM7025.PDF Dribbler Gear Spec Sheet] | ||

| + | *Roller gear bore must be reamed out to 4mm | ||

| + | *Powers the dribbler roller - is recessed into the roller itself | ||

| + | |||

| + | ===Plates=== | ||

| + | =====Swing===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 8885K13 | ||

| + | :Description: Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12" | ||

| + | :Cost: $21.73 | ||

| + | *Contains the roller shaft, the motor mounts, spacers, and hinge shafts | ||

| + | *Material is same and shared with Omniwheel plates | ||

| + | *Left and right swings are identical | ||

| + | |||

| + | =====Motor plate===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 8885K13 | ||

| + | :Description: Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12" | ||

| + | :Cost: $21.73 | ||

| + | *Supports motor and connects to the 2 spacers in assembly | ||

| + | *Material is same and shared with Omniwheel plates | ||

| + | |||

| + | =====Cross Plate===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 8885K13 | ||

| + | :Description: Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12" | ||

| + | :Cost: $21.73 | ||

| + | *Connects both mounting blocks and provides mechanical limitation for swing and torsion springs | ||

| + | *Material is same and shared with Omniwheel plates | ||

| + | |||

| + | ===Standoffs=== | ||

| + | =====Standoff===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 9062K271 | ||

| + | :Description: Alloy 6061 Aluminum Precision-Ground Rod 5/16" Diameter, 1' Length | ||

| + | :Cost: $9.10 | ||

| + | *Standoff between swing and motor plate | ||

| + | |||

| + | =====2" Hex Standoff===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 91780A339 | ||

| + | :Description: Aluminum Female Threaded Hex Standoff 1/4" Hex, 2" Length, 6-32 Screw Size | ||

| + | :Cost: $.88 | ||

| + | *Hex standoff between motor plate and swing | ||

| + | *Both torsion springs anchor into the standoff | ||

| + | |||

| + | ===Fasteners=== | ||

| + | =====6-32 x 1/4" socket cap screw===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 92220A141 | ||

| + | :Description: 6-32 x 1/4" steel, low profile, socket cap screw | ||

| + | :Cost: $7.22 for 25 | ||

| + | *Connects the swing and hex standoff | ||

| + | |||

| + | =====6-32 x 3/4" socket cap screw===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 93615A217 | ||

| + | :Description: 6-32 x 3/4" 18-8 stainless steel, low profile, socket cap screw | ||

| + | :Cost: $12.72 for 25 | ||

| + | *Connects the swing, motor plate, and hex standoff | ||

| + | |||

| + | =====8-32 Lock Nut===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 90633A009 | ||

| + | :Description: Steel Hex Nylon-Insert Locknut, 8-32 Screw Size, 11/32" W, 11/64" H | ||

| + | :Cost: $2.21 each - STOCK | ||

| + | *Constrains the dribbler and hinge shafts | ||

| + | |||

| + | =====4-40 Set Screw===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 91375A105 | ||

| + | :Description: Alloy Steel Cup Point Socket Set Screw 4-40 Thread, 3/16" Length | ||

| + | :Cost: $7.99 for pack of 100 | ||

| + | *Pins dribbler roller to the dribbler shaft | ||

| + | |||

| + | ===Shaft=== | ||

| + | =====Hinge shaft===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 8116K3 | ||

| + | :Description: A2 Tool Steel Tight-Tolerance Metric Rod 4 mm Diameter, 3' Length | ||

| + | :Cost: $6.10 | ||

| + | *Joint between swings and mounting blocks | ||

| + | |||

| + | =====Dribbler shaft===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 8116K3 | ||

| + | :Description: A2 Tool Steel Tight-Tolerance Metric Rod 4 mm Diameter, 3' Length | ||

| + | :Cost: $6.10 | ||

| + | *Roller and dribbler gear spin on dribbler shaft | ||

| + | *Material is shared with the hinge shaft | ||

| + | |||

| + | ===Springs=== | ||

| + | =====Left Torsion Spring===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 9271K35 | ||

| + | :Description: 1.375 lbf-in of torque. Music Wire Torsion Spring 90 Deg Angle, .309" Coil OD, .040" Wire, Cw/Lh, Packs of 6 | ||

| + | :Cost: $6.56 for 6 | ||

| + | *Left hand wound torsion spring | ||

| + | *Rests on hinge shaft and provides cushioning for ball impact | ||

| + | |||

| + | =====Right Torsion Spring===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 9271K33 | ||

| + | :Description: 1.375 lbf-in of torque. Music Wire Torsion Spring 90 Deg Angle, .309" Coil OD, .040" Wire, Cw/Rh, Packs of 6 | ||

| + | :Cost: $6.56 for 6 | ||

| + | *Right hand wound torsion spring | ||

| + | *Rests on hinge shaft and provides cushioning for ball impact | ||

| + | |||

| + | ===Other=== | ||

| + | =====Mounting block===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 3511T11 | ||

| + | :Description: Alloy 6061 Aluminum Ground Flat Stock .250" Thick, 6" X 6" Size | ||

| + | :Cost: $45.44 each - STOCK | ||

| + | *Connects entire dribbler assembly to the robot | ||

| + | |||

| + | =====4mm snap thrust bearing===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 7817K33 | ||

| + | :Description: Metric Nylon Snap-in Thrust Bearing for 4mm Shaft Dia, 1.45-2.34 mm Sheet Metal Thick | ||

| + | :Cost: $1.32 each | ||

| + | *supports dribbler shaft in the swing | ||

| + | |||

| + | =====3/8" Washer===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 93286A009 | ||

| + | :Description: Aluminum washer 3/8" OD,.175" ID, 1/32" thick | ||

| + | :Cost: $3.52 for 100 | ||

| + | *Washer between the swing and hex standoff | ||

| + | |||

| + | =====Neoprene Rubber Tube===== | ||

| + | :Vendor: McMaster-Carr | ||

| + | :Part No.: 7505K86 | ||

| + | :Description: Ultra-Flex Neoprene Rubber Heat-Shrink Tubing 3/4" Expanded ID, 3/8" Shrunken ID, | ||

| + | :Cost: $8.97 | ||

| + | *Roller and dribbler gear spin on dribbler shaft | ||

| + | *Material is shared with the hinge shaft | ||

| + | |||

| + | ==Calculations== | ||

| + | =====Torsion Spring===== | ||

| + | * Analysis was done using the Work-Energy Principle with the assumption that the only work done is from the torsion spring and gravity. Because the dribbler assembly swings and has zero velocity at both positions, only the kinetic energy of the ball was used, at its maximum value of 10 m/s | ||

| + | |||

| + | =====Roller Speed===== | ||

| + | * Gears were selected for a gear ratio lower than 2007. The 2008 ratio is 1.5. This was with the hope of having more torque available for the roller to grip the ball. | ||

| + | |||

| + | =====Dimensional Analysis===== | ||

| + | * Using the Buckingham Pi theorem, an unknown function expressing the moment the dribbler roller puts on the ball based on other parameters was developed. | ||

| + | * The inputs to this function can now guide the testing plan for the dribbler | ||

| + | * The mom<math>f(mu)</math> | ||

| + | [[Image:Dribblerdimension.png]] | ||

| + | |||

| + | ==Notes== | ||

| + | * 4mm steel shaft chosen to increase strength to prevent bending of dribbler shaft when hit with a ball | ||

| + | *roller diameter - .5" | ||

| + | *dribbler shaft still slides free in between two snap-in thrust bearings and can be removed to allow the roller to be changed out | ||

| + | *several 4mm holes were widened to .170" holes to allow easy assembly with the 8-32 threaded shaft | ||

| + | *it proved very difficult to even squeeze 4mm shaft through the thrust bearings | ||

| + | *due to unknown errors a few addtional washers were placed in the assembly | ||

| + | *on the left arm a small cut was created to allow the motor shaft to protrude | ||

| + | *a new motor plate was created and fits flush to the motor | ||

| + | *it was found when the original motor plate was attached and fastended, it would add a high amount of friction and actually stalled the motor | ||

| + | *a big issue is that the 2 dribbler arms must be connected around either the back or the front - and not rotate independently | ||

| + | *this independent rotation swivels the motor around, putting more stress and wear on the gears, or makes the gears not even mesh | ||

| + | *the small standoff closest to the motor was replaced with a hex standoff, as it would hit the motor gear slightly if the motor was pushed up a bit | ||

| + | *a 4mm die will be purchased to thread the shafts, preventing boring of 4mm holes | ||

| − | * | + | ==Changes from Prototype== |

| + | * a standoff now near the roller itself to provide structural stability, connect the two formerly independent swing arms, and protect the motor from ball impacts | ||

| + | * clinch nuts will be used to anchor the assembly to the robot, making it much easier to remove the dribbler assembly | ||

| + | * the motor mount plate now connects to the hinge axis, the motor, and the front standoff | ||

| + | * the 4mm hinge and roller shafts will be threaded to fit 4mm hex nuts | ||

| + | * the gear ratio between the motor and roller has increased from 1:1.4 to 1:1.75 | ||

| + | * the dribbler roller diameter has increased from .5" to 5/8" | ||

| − | |||

==Dribbler bar prototypes== | ==Dribbler bar prototypes== | ||

| Line 41: | Line 300: | ||

[[image:dribblerprototype.png|500 px|Dribbler bar prototype drawing]] | [[image:dribblerprototype.png|500 px|Dribbler bar prototype drawing]] | ||

| − | |||

===dribbler bar prototypes=== | ===dribbler bar prototypes=== | ||

*3/4" diameter aluminum bar stock | *3/4" diameter aluminum bar stock | ||

| Line 55: | Line 313: | ||

**pack of 100 for $3.03 | **pack of 100 for $3.03 | ||

**McMaster part number 98543A101 | **McMaster part number 98543A101 | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==2007 Dribbler== | ==2007 Dribbler== | ||

| Line 117: | Line 343: | ||

*nominal dribbler bar speed = 28200/5.4*1.5 = 7833 RPM. It is, of course, adjustable by software. | *nominal dribbler bar speed = 28200/5.4*1.5 = 7833 RPM. It is, of course, adjustable by software. | ||

| + | |||

| + | [[Category: RC Mechanical]] | ||

| + | [[Category:2007-2008]] | ||

Latest revision as of 19:50, 24 May 2020

This page contains the information and documentation of the 2008 dribbler system

Contents

Assembly Structure

| PART NAME | PART NUMBER | QUANTITY |

|---|---|---|

| Mounting Block | RC-2008-04-01 | 2 |

| Swing | RC-2008-04-02 | 2 |

| Motor Plate | RC-2008-04-03 | 1 |

| Standoff | RC-2008-04-04 | 2 |

| Hinge Shaft | RC-2008-04-05 | 1 |

| 8-32 Lock Nut | RC-2008-04-06 | 4 |

| 2" Hex Standoff | RC-2008-04-07 | 1 |

| Dribbler Motor | RC-2008-04-08 | 1 |

| M2x5 Screw | RC-2008-04-09 | 2 |

| Dribbler Motor Gear | RC-2008-04-10 | 1 |

| 6-32 x 3/4 Screw | RC-2008-04-11 | 1 |

| Cross Plate | RC-2008-04-12 | 1 |

| 4mm Snap Bearing | RC-2008-04-13 | 2 |

| Dribbler Shaft | RC-2008-04-14 | 1 |

| Dribbler Roller | RC-2008-04-15 | 1 |

| Dribbler Roller Gear | RC-2008-04-16 | 1 |

| Left Torsion Spring | RC-2008-04-17 | 1 |

| Right Torsion Spring | RC-2008-04-18 | 1 |

| 6-32 x 1/4 Screw | RC-2008-04-19 | 1 |

| 3/8" Washer | RC-2008-04-20 | 1 |

| Neoprene Rubber Tube | RC-2008-04-21 | 1 |

| 4-40 Set Screw | RC-2008-04-22 | 1 |

Parts & Components

Motor

Fleet motor from Maxon

- Part no: 266521 with attached gear head 118184.

- 5.4 gear reduction

- cost: $146.20 each

- Motor Data Sheet

- Gearhead Data Sheet

Vendor: MicroMo

- Motor: 12V DC brushless servo motor #E-1628B

- $147.10 each

- Planetary gearhead: #E-167 gear reduction: 14

- Complete assembly 1628-V-0003

Cost: $200.40 each

- Electrical specification

- 12 Volts

- must have position or speed encoders

- brushless DC

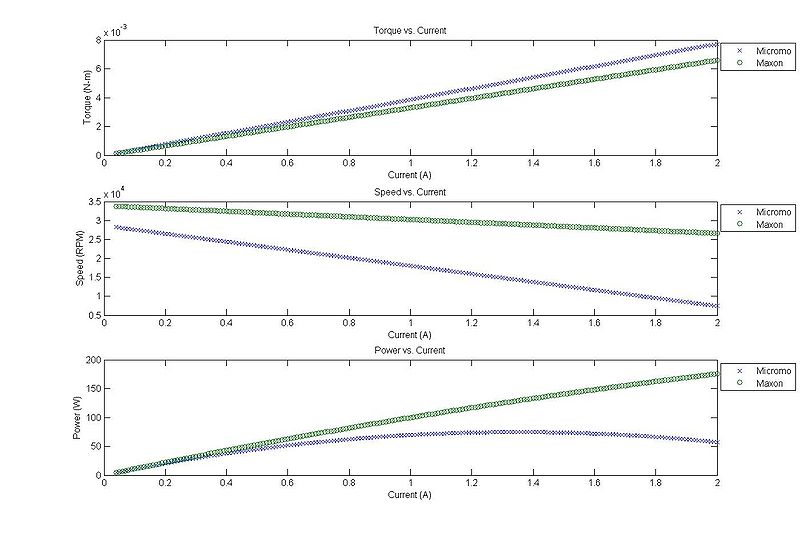

- Maxon motor, the same CMU uses, was chosen for the fleet. This was based on 4wk shorter lead time, $60 cheaper per motor, and significantly greater performance as can be seen from the figures generated by a Matlab script

Gears

Motor gear

- Vendor: SDP/SI

- Part No.: A 1B 2MYK05035

- Description: Module 0.5, 35 Teeth, 20° Pressure Angle, Brass Gear with set screw, 3mm bore, 17.5mm PD

- Cost: $7.47

- Drawing:Motor Gear Spec Sheet

- Connects directly to output of motor and powers dribbler roller

Roller gear

- Vendor: SDP/SI

- Part No.: A 1B 2MYK05025

- Description: Module 0.5, 25 Teeth, 20° Pressure Angle, Brass Gear with set screw, 3mm bore, 12.5mm PD

- Cost: $6.03

- Drawing:Dribbler Gear Spec Sheet

- Roller gear bore must be reamed out to 4mm

- Powers the dribbler roller - is recessed into the roller itself

Plates

Swing

- Vendor: McMaster-Carr

- Part No.: 8885K13

- Description: Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12"

- Cost: $21.73

- Contains the roller shaft, the motor mounts, spacers, and hinge shafts

- Material is same and shared with Omniwheel plates

- Left and right swings are identical

Motor plate

- Vendor: McMaster-Carr

- Part No.: 8885K13

- Description: Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12"

- Cost: $21.73

- Supports motor and connects to the 2 spacers in assembly

- Material is same and shared with Omniwheel plates

Cross Plate

- Vendor: McMaster-Carr

- Part No.: 8885K13

- Description: Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12"

- Cost: $21.73

- Connects both mounting blocks and provides mechanical limitation for swing and torsion springs

- Material is same and shared with Omniwheel plates

Standoffs

Standoff

- Vendor: McMaster-Carr

- Part No.: 9062K271

- Description: Alloy 6061 Aluminum Precision-Ground Rod 5/16" Diameter, 1' Length

- Cost: $9.10

- Standoff between swing and motor plate

2" Hex Standoff

- Vendor: McMaster-Carr

- Part No.: 91780A339

- Description: Aluminum Female Threaded Hex Standoff 1/4" Hex, 2" Length, 6-32 Screw Size

- Cost: $.88

- Hex standoff between motor plate and swing

- Both torsion springs anchor into the standoff

Fasteners

6-32 x 1/4" socket cap screw

- Vendor: McMaster-Carr

- Part No.: 92220A141

- Description: 6-32 x 1/4" steel, low profile, socket cap screw

- Cost: $7.22 for 25

- Connects the swing and hex standoff

6-32 x 3/4" socket cap screw

- Vendor: McMaster-Carr

- Part No.: 93615A217

- Description: 6-32 x 3/4" 18-8 stainless steel, low profile, socket cap screw

- Cost: $12.72 for 25

- Connects the swing, motor plate, and hex standoff

8-32 Lock Nut

- Vendor: McMaster-Carr

- Part No.: 90633A009

- Description: Steel Hex Nylon-Insert Locknut, 8-32 Screw Size, 11/32" W, 11/64" H

- Cost: $2.21 each - STOCK

- Constrains the dribbler and hinge shafts

4-40 Set Screw

- Vendor: McMaster-Carr

- Part No.: 91375A105

- Description: Alloy Steel Cup Point Socket Set Screw 4-40 Thread, 3/16" Length

- Cost: $7.99 for pack of 100

- Pins dribbler roller to the dribbler shaft

Shaft

Hinge shaft

- Vendor: McMaster-Carr

- Part No.: 8116K3

- Description: A2 Tool Steel Tight-Tolerance Metric Rod 4 mm Diameter, 3' Length

- Cost: $6.10

- Joint between swings and mounting blocks

Dribbler shaft

- Vendor: McMaster-Carr

- Part No.: 8116K3

- Description: A2 Tool Steel Tight-Tolerance Metric Rod 4 mm Diameter, 3' Length

- Cost: $6.10

- Roller and dribbler gear spin on dribbler shaft

- Material is shared with the hinge shaft

Springs

Left Torsion Spring

- Vendor: McMaster-Carr

- Part No.: 9271K35

- Description: 1.375 lbf-in of torque. Music Wire Torsion Spring 90 Deg Angle, .309" Coil OD, .040" Wire, Cw/Lh, Packs of 6

- Cost: $6.56 for 6

- Left hand wound torsion spring

- Rests on hinge shaft and provides cushioning for ball impact

Right Torsion Spring

- Vendor: McMaster-Carr

- Part No.: 9271K33

- Description: 1.375 lbf-in of torque. Music Wire Torsion Spring 90 Deg Angle, .309" Coil OD, .040" Wire, Cw/Rh, Packs of 6

- Cost: $6.56 for 6

- Right hand wound torsion spring

- Rests on hinge shaft and provides cushioning for ball impact

Other

Mounting block

- Vendor: McMaster-Carr

- Part No.: 3511T11

- Description: Alloy 6061 Aluminum Ground Flat Stock .250" Thick, 6" X 6" Size

- Cost: $45.44 each - STOCK

- Connects entire dribbler assembly to the robot

4mm snap thrust bearing

- Vendor: McMaster-Carr

- Part No.: 7817K33

- Description: Metric Nylon Snap-in Thrust Bearing for 4mm Shaft Dia, 1.45-2.34 mm Sheet Metal Thick

- Cost: $1.32 each

- supports dribbler shaft in the swing

3/8" Washer

- Vendor: McMaster-Carr

- Part No.: 93286A009

- Description: Aluminum washer 3/8" OD,.175" ID, 1/32" thick

- Cost: $3.52 for 100

- Washer between the swing and hex standoff

Neoprene Rubber Tube

- Vendor: McMaster-Carr

- Part No.: 7505K86

- Description: Ultra-Flex Neoprene Rubber Heat-Shrink Tubing 3/4" Expanded ID, 3/8" Shrunken ID,

- Cost: $8.97

- Roller and dribbler gear spin on dribbler shaft

- Material is shared with the hinge shaft

Calculations

Torsion Spring

- Analysis was done using the Work-Energy Principle with the assumption that the only work done is from the torsion spring and gravity. Because the dribbler assembly swings and has zero velocity at both positions, only the kinetic energy of the ball was used, at its maximum value of 10 m/s

Roller Speed

- Gears were selected for a gear ratio lower than 2007. The 2008 ratio is 1.5. This was with the hope of having more torque available for the roller to grip the ball.

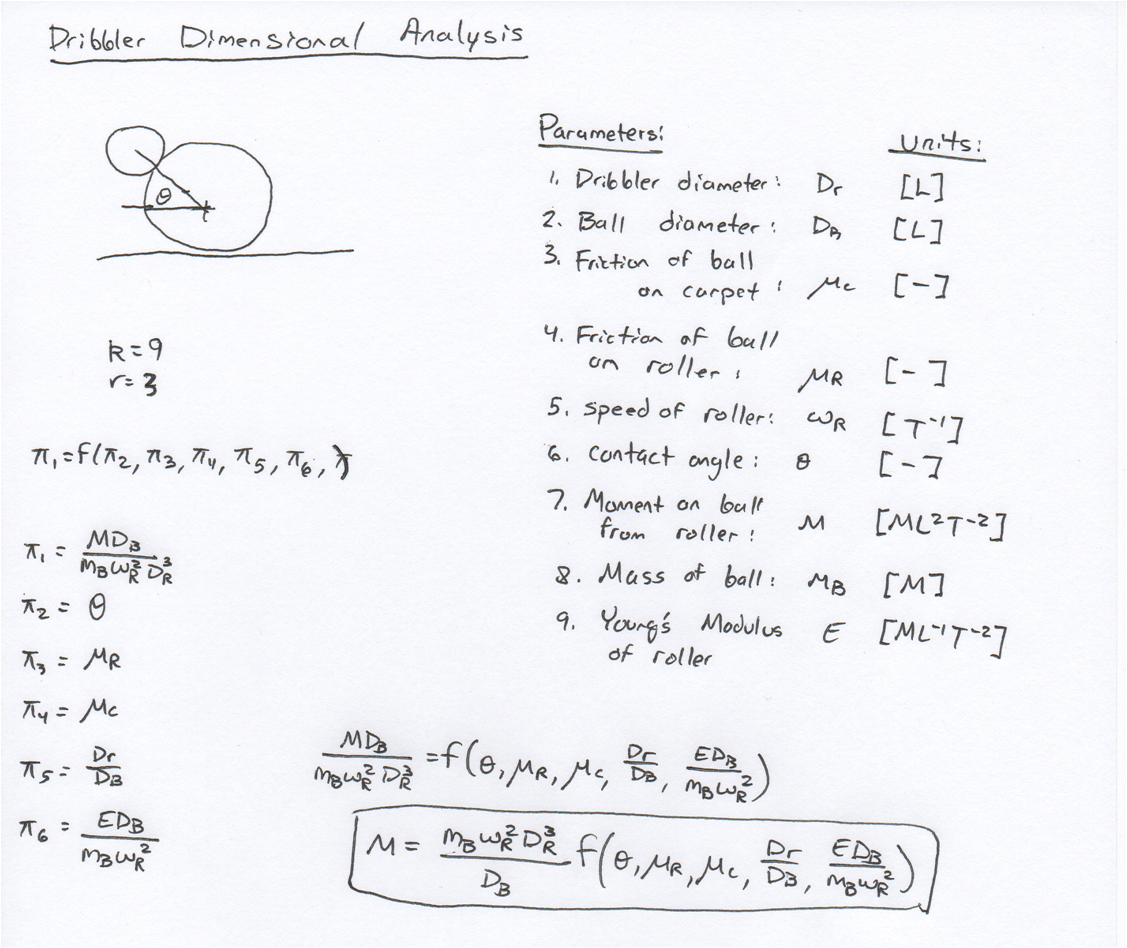

Dimensional Analysis

- Using the Buckingham Pi theorem, an unknown function expressing the moment the dribbler roller puts on the ball based on other parameters was developed.

- The inputs to this function can now guide the testing plan for the dribbler

- The mom

Notes

- 4mm steel shaft chosen to increase strength to prevent bending of dribbler shaft when hit with a ball

- roller diameter - .5"

- dribbler shaft still slides free in between two snap-in thrust bearings and can be removed to allow the roller to be changed out

- several 4mm holes were widened to .170" holes to allow easy assembly with the 8-32 threaded shaft

- it proved very difficult to even squeeze 4mm shaft through the thrust bearings

- due to unknown errors a few addtional washers were placed in the assembly

- on the left arm a small cut was created to allow the motor shaft to protrude

- a new motor plate was created and fits flush to the motor

- it was found when the original motor plate was attached and fastended, it would add a high amount of friction and actually stalled the motor

- a big issue is that the 2 dribbler arms must be connected around either the back or the front - and not rotate independently

- this independent rotation swivels the motor around, putting more stress and wear on the gears, or makes the gears not even mesh

- the small standoff closest to the motor was replaced with a hex standoff, as it would hit the motor gear slightly if the motor was pushed up a bit

- a 4mm die will be purchased to thread the shafts, preventing boring of 4mm holes

Changes from Prototype

- a standoff now near the roller itself to provide structural stability, connect the two formerly independent swing arms, and protect the motor from ball impacts

- clinch nuts will be used to anchor the assembly to the robot, making it much easier to remove the dribbler assembly

- the motor mount plate now connects to the hinge axis, the motor, and the front standoff

- the 4mm hinge and roller shafts will be threaded to fit 4mm hex nuts

- the gear ratio between the motor and roller has increased from 1:1.4 to 1:1.75

- the dribbler roller diameter has increased from .5" to 5/8"

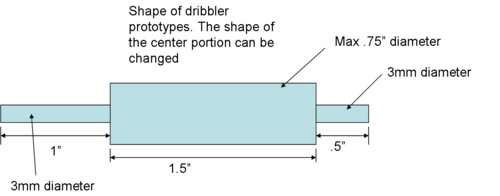

Dribbler bar prototypes

- shaft diameter on ends of bar - 3mm

- maximum diameter of dribbler - .75"

- the dribbler bar prototypes will be lathed and done coated with neoprene heat shrink

dribbler bar prototypes

- 3/4" diameter aluminum bar stock

- $8.34

- McMaster part number 6750K181

- 3mm diameter aluminum bar stock

- $6.94

- McMaster part number 1681T21

- 3/4" neoprene heat shrink

- pack of 5 for $8.97

- McMaster part number 7505K86

- 3mm e-clips

- pack of 100 for $3.03

- McMaster part number 98543A101

2007 Dribbler

Drive gear

- attached to the motor

- SDP/SI A-1B-2MYK05045 Data sheet

- 45 teeth, 3mm bore, 22.5mm pitch diameter

Dribbler gear

- attached to the roller. This is done by pressing having a set screw in the gear interfere with the roller. Both the gear and roller are free to spin on the shaft, which permitting easy change.

- SDP/SI A-1B-2MYKO5020H Data sheet

- 20 teeth, 3mm bore, 10mm pitch diameter

- gear ratio from motor to drilbber = 2.25

Motor

- 15.9mm diameter, 3mm output shaft

Specs from CMU

- Dribbler motor gear from SDP-SI: S10T05M042A0303 Module 0.5, 42 Teeth, 20° Pressure Angle , 2024 Aluminum alloy Gear

- Dribbler bar gear from SDP-SI: S10T05M028A0305 Module 0.5, 28 Teeth, 20° Pressure Angle , 2024 Aluminum alloy Gear

- spur gear reduction 1:1.5

- Dribbler Motor - Maxon

- 266521

- http://test.maxonmotor.com/docsx/Download/catalog_2007/Pdf/07_154_e.pdf

- nominal speed 28200 rpm

- Gearhead

- 118184 - Maxon

- http://test.maxonmotor.com/docsx/Download/catalog_2007/Pdf/07_215_e.pdf

- reduction 5.4:1

- nominal dribbler bar speed = 28200/5.4*1.5 = 7833 RPM. It is, of course, adjustable by software.