RoboCup Mechanical 2015

This page houses the 2015 RoboCup Mechanical efforts. Mechanical tasks for the 2015 competition year can be most easily summarized as a complete redesign of the SSL fleet.

Mechanical team meets Tuesday, 6:30-9pm Sunday, 1-5pm. More hours will be announced as deadlines approach.

Contents

Background

Current Robots

The team has taken part in RoboCup every year since 2008*. Two different fleets of robots are used: a fleet designed in 2008, and a fleet designed in 2011. The 2008 fleet sports a solenoid powered kicker mechanism and a fixed dribbler. The 2011 fleet sports solenoid powered kicker AND chipper mechanisms, along with a fixed dribbler and encoders on the motors.

Previous Issues

Due to an error in the tolerances of shaft components for the 2011 fleet, the drivetrain of these robots have suffered tremendously, resulting in decayed performance of the motors. This renders mostly all 2011 robots functionally incapable. Thus, the most reliable robots have been those designed in 2008. However, the 2008 robots lack encoders, and without these sensors, this makes control of the robots significantly more challenging for the software team.

Improvements

Due to these challenges, it has been determined that a complete rebuild of the robots is required to continue to be competitive in the RoboCup SSL. Particular emphasis is being placed on designing passive mechanisms that aid the software team in having finer control over the robots and the ball.

Requirements

Primary Goals

The team for the 2015 competition year has met several times to discuss the primary goals for a new fleet of robots. These requirements are outlined below, in order of highest priority to lowest priority.

- Encoders on the motors

- Robust drivetrain mounts

- Damped dribbler

- Lower profile solenoids

- Superior traction/grip for the wheels

- Robust shell design

Secondary Goals

The team has also considered other desired characteristics of the robots that are not necessarily competition-oriented goals. The list is below (in no particular order).

- Improved tolerances for the omniwheel (previous designs have significant play in this subsystem)

- Improved aesthetics for the robot shell

- Ease of attachment/removal of electrical boards

- Low center of gravity

Specifications

- Ball speed after being kicked - 8 m/s

- Dribbler bar speed - 8000 rpm

- Compress time (time for dribbler to absorb ball's energy and compress) - .2 seconds

- No more than 20% of the ball's area (seen from top view) may be occupied by the robot - a critical Robocup SSL Rule

Mechanical Systems

Drivetrain

Integration

Ball Control

Testing

Machining Notes

Schedule

- Motors shipment date - March 26, 2015

- Delivery of Prototype - End of March, beginning of April 2016

- Delivery of Fleet - End of April 2015

Meetings

Attendance information is logged on paper for every meeting and submitted to the College of Computing for record-keeping.

Documentation

Testing

General Specifications

Coordinate system:

- Origin at the very center of the bottom plate, 0.25" below it in the y axis (height)

- The Z axis is oriented towards the rear, so the mouth is in negative

- The X axis is oriented towards the right of the robot

Mass:

- 4.68 bl mas

Mass Moment of Inertia:

- Ixx = 18.5298 lbmass in2

- Ixy = -0.459 lbmass in2

- Ixz = 0.089 lbmass in2

- Iyy = 25.488 lbmass in2

- Iyz = -0.159 lbmass in2

- Izz = 17.66 lbmass in2

Center of Mass:

- x = -0.0009.

- z = -0.3

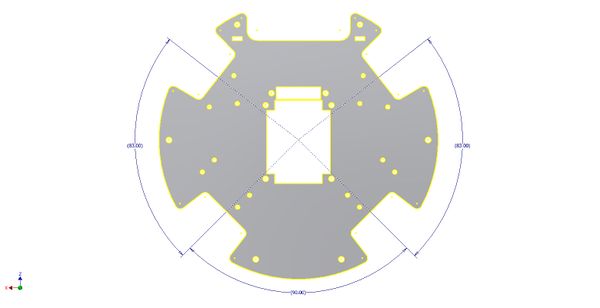

Wheel Placement:

Wheel Angles:

- The rear wheels are oriented at 45� from the z axis

- The front wheels are oriented at 83� from the rear motors

Wheel Distance:

The contact point with of the omniwheel and the surface is 3.144" from the center axis.

Quick Notes

- Field Size:

- For the 2014 year, two options were available for the field size:

- Single-size field: 6050mm x 4050mm

- Double-size field: 8090mm x 6050mm

- For the 2015 competition year, the field size is locked in as the "Double-size field": 8090mm x 6050mm

- For the 2014 year, two options were available for the field size:

- Max ball speed - 8 m/s

- Ball diameter - 43 mm

- Ball mass - 46 grams

- Ball material - DuPont Surlyn Ionomer Dupont's Surlyn Page

- Coefficient of static friction of golf ball on felt carpet - .66

- last two points from Cornell 2003 Mechanical Documentation

Useful Links

- To be completed and appended to very soon