RC09-Omni

Jump to navigation

Jump to search

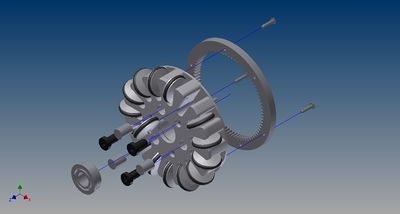

As part of the RoboCup 2009 Mechanical, the Omni Wheels allow the robots to move in any direction at anytime.

Contents

Drawings

Assembly Structure

Parts & Components

Amounts are based on per robot. Materials are in sizes for prototyping not lowest cost per robot volume pricing if available is in parenthesis.

Stock

Plate - Wheel Plate

- Vendor - McMaster-Carr

- Part No. - 8885K13

- Cost - $21.63

- Description - Alloy 7075 Aluminum Sheet .063" Thick, 12" X 12"

Plate - Wheel Body

- Vendor - McMaster-Carr

- Part No. - 9246K23

- Cost - $28.51

- Description - Multipurpose Aluminum (Alloy 6061) 3/8" Thick, 12" X 12"

Shaft - Rollers

- Vendor - McMaster-Carr

- Part No. - 9063K243

- Cost - $17.48

- Description - Alloy 7075 Aluminum Precision Ground Rod 1/8" Diameter, 3' Length

- Note: Usually ships within 2 weeks.

Fasteners

6-32 Low Head Socket Cap Screw

- Vendor - McMaster-Carr

- Part No. - 92220A141

- Cost - $7.42 (packs of 25)

- Description - Alloy Steel Low Head Socket Cap Screw 6-32 Thread, 1/4" Length

3/16" Dowel Pin

- Vendor - MSC

- Part No. - 88231758

- Cost - $43.08 (per 100)

- Description - Precision Ground Dowel Pins - Stainless Steel Type: Dowel Pin Diameter: 3/16 Overall Length: 1/4 Material: Stainless Steel - 416 SS Finish/Coating: Bright

1/16" Dowel Pin

- Vendor - MSC

- Part No. - 88231196

- Cost - $19.83 (per 100)

- Description - Precision Ground Dowel Pins - Stainless Steel Type: Dowel Pin Diameter: 1/16 Overall Length: 1/4 Material: Stainless Steel - 416 SS Finish/Coating: Bright

Other

O-Ring

- Vendor - McMaster-Carr

- Part No. - 94115K012

- Cost - $2.87 (Pks of 100)

- Quantity -

- Description - Neoprene O-Ring AS568A Dash Number 012

Assembly

Tools needed

- 3 axis CNC Mill

- WaterJet

- Hex Keys

- Press

- CNC Lathe(parts are outsourced)

Instructions

Fabrication

- The Omni body is fabricated through the use of the HAAS a 3 axis CNC Mill. The 3/8 plate is used for this process

- The Omni Plate or Wheel plate is made with the Waterjet using the .063 7075 aluminum sheet.

- Due to the Omni Plates being quite small it is advised that you connect at least 2 together and then grinding away the small connection.

- The omni rollers are outsourced. If one has access to a CNC lathe then one could fabricate one's own.

- The planetary gear is also outsourced.

Assembly

- Put o-rings in the groove in the rollers and press the 1/16 dowel pins into the hole.

- Use the press to press the bearing into the center hole of the omni body and the dowel pins into the 3 holes surrounding it.

- On the back of the omni body place the plastic inserts into the small holes.

- Attach the planetary gear by screwing in the 0-80 screws into the plastic inserts.

- Place rollers with o-rings and dowel pins into the grooves on the omni body

- Fit plate on top of the omni body and secure it by screwing in the 6-32x1/4 screws.

Cost Estimates

Action Log

- 10/19/2008 - Initial revised roller design completed.

- 11/02/2008 - Added new groove style for new rollers.

- 11/09/2008 - Refined roller design.

- 12/30/2008 - Resized to match internal gear dimensions.

- 01/13/2009 - Added fillets.

- 02/01/2009 - Drawing for rollers produced and ready to be posted for quote.

- 02/22/2009 - Design for prototype completed.

- 03/15/2009 - Rollers posted to mfg.com for quote.

- 03/17/2009 - Design revised. Internal gear added to omni body.

- 03/25/2009 - Supplier for rollers selected.

- 04/08/2009 - All 400 Rollers arrive for omni wheels.

- 05/05/2009 - 1/2 of rollers are assembled.

- 07/18/2009 - Omni bodies CAM'd.

- 01/26/2010 - Omni plates for prototype water jetted.

- 02/03/2010 - Tooling required to make omni bodies arrives.

- 02/13/2010 - First omni body completed. Problems encountered with automated tapping of 6-32s.

- 03/20/2010 - Last omni body for prototype made.

- 03/23/2010 - Revisions made to omni design to allow for better draining of retaining compound, symmetrical plate positioning, and new bearings.

- 04/03/2010 - First fleet omni body made. Process is down to 2hrs.