Difference between revisions of "RC09-Dribbler"

m (recategorizing) |

Kberzinch3 (talk | contribs) m (Text replacement - "Category: Year: 2008-2009" to "Category:2008-2009") |

||

| Line 113: | Line 113: | ||

[[Category: RoboCup]] | [[Category: RoboCup]] | ||

[[Category: Mechanical]] | [[Category: Mechanical]] | ||

| − | [[Category | + | [[Category:2008-2009]] |

Revision as of 21:58, 18 July 2018

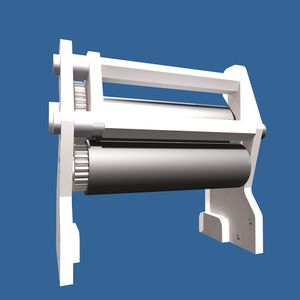

As part of the RoboCup 2009 Mechanical, the dribbler provides back spin on the golf ball and allows the robot to steal the ball from opponents and move with it. This unit also hold the ball sensor LED's.

Contents

Testing

Dribbler Bar Type

The current plan for the 2009 Dribbler is to have it be segmented. Segmenting creates two sections of dribbler with a gap in between. Theoretically, this allows for more ball control. The Mexican team used this set up in 2008 (see here). The gap in between is going to be between a quarter to a third of the length of the dribbler.

Performance Assessment

To measure last years performance and game play. This will be determined by receiving a kick and grabbing a stationary ball all under computer control. These results will be used as a benchmark to our new Dribbler model.

Pouring

We might want to look into pouring a mold of silicon rubber for the Dribbler assembly. This will be easier to put the rubber on the shaft. We don't know how well this will work, but we should do tests to see its effectiveness.

Candidates

- 75115A65 McMaster-Carr ($17.89)

Obstacles

- Make an outer mold.

- Make inner mold/shaft.

- Develop out gassing technique for pour.

Parts & Components

Motors

Dribbler Motor

- Vendor - Maxon

- Part No. - 266521 (with attached gear head 118184 5.4 gear reduction)

- Cost - $146.20 each

- Notes

Gears & Bearings

Motor Gear (Supplier A)

- Vendor - WM Berg

- Part No. - PFS80-46

- Description - Module 0.5, 34 Teeth, 20° Pressure Angle, Stainless Steel Gear with hub set screw, 3mm bore, 23mm PD

- Cost - $20.41

- Drawing - Motor Gear Spec Sheet

Motor Gear (Supplier B)

- Vendor - SDP/SI

- Part No. - S10T05M046S0303

- Description - Module 0.5, 34 Teeth, 20° Pressure Angle, Stainless Steel Gear with hub set screw, 3mm bore, 23mm PD

- Cost - $13.96

Output Gear (Supplier A)

- Vendor - WM Berg

- Part No. - PFS80-26

- Description - Module 0.5, 20 Teeth, 20° Pressure Angle, Stainless Steel Gear with set screw, 3mm bore, 13mm PD

- Cost - $17.42

- Drawing - Dribbler Gear Spec Sheet

Output Gear (Supplier B)

- Vendor - SDP/SI

- Part No. - S10T05M026S0303

- Description - Module 0.5, 20 Teeth, 20° Pressure Angle, Stainless Steel Gear with set screw, 3mm bore, 13mm PD

- Cost - $11.52

Bearing (1/8" Shaft)

- Vendor - Grainger

- Part No. - 1ZEH7

- Cost - $7.16 Each

- Description - Miniature Ball Bearing, Open, Flanged, Bore Dia 0.1250 In, Outside Dia 0.2500 In, Width 0.0937 In, Flange Dia 0.2960 In, Flange Thickness 0.0230 In, ABEC Level 3

- Info - Web Link

Stock

RTV

- Vendor - McMaster-Carr

- Part No. - 75115A65

- Description - Loctite Gray Silicone Gasket Maker Number 18718, 2.36 Ounce Tube

- Cost - $17.89

Shaft

- Vendor - McMaster-Carr

- Part No. - 8974K25

- Description - Multipurpose Aluminum (Alloy 6061) 7/16" Diameter X 6' Length

- Cost - $13.51

Fasteners

1st Stand off

- Vendor - Digi-Key

- Part No. - 4856K-ND

- Description - STANDOFF HEX 6-32THR ALUM 2"

- Cost - $0.6775 each (must buy in packs of 100)

1/4" Hex Stand off

- Vendor - Digi-Key

- Part No. - 2214K-ND

- Description - STANDOFF HEX 6-32THR ALUM 2"

- Cost - $1.225 each (must buy in packs of 10)

6-32 x 5/8 Low Head Socket Cap Screw

- Vendor - McMaster-Carr

- Part No. - 92220A144

- Description - Alloy Steel Low Head Socket Cap Screw 6-32 Thread, 5/8" Length

- Cost - $9.63 (pkg 25)

Action Log

- 10/12/2008 - Segmented dribbler prototype design completed.

- 10/16/2008 - Acquisition of silicone gasket sealer to test in mold.

- 11/02/2008 - The spare dribbler from 08 was modified to be a segmented.

- Note - The rubber as damaged some while on the lathe. Patched was tested with gasket sealer.

- 11/09/2008 - Impact tester was modified to allow for testing of receiving a pass.

- 03/17/2009 - Housing preliminary sizing completed.

- 03/18/2009 - Gearing Reselected.

- 03/19/2009 - Preliminary design completed.

- 03/20/2009 - Full initial design completed and fits with out interference.

- 03/22/2009 - Fabrication touch ups added.

- 04/05/2009 - More fabrication fixes added. (mounting hole placement)

- 04/13/2009 - Dribbler roller suppler found on mfg.com.

- 05/15/2009 - Dribbler rollers arrive.

- 07/18/2009 - Dribbler side plates CAM'd.

- 12/29/2009 - Dribbler machined and assembled.

- 02/07/2010 - All parts of dribbler assembled and tested. Performance is acceptable will retest with chipper.